Video Article Open Access

Solvent-Free Fabrication and Characterization of 3D Printable Fluoropolymer-Ferroceramic Composite for Piezoelectric Applications

Gopi Kompelli1*, Rolanas Daukševičius1, Marius Rimašauskas2, Elena Jasiūnienė3, Vaidotas Cicėnas3

1Kaunas University of Technology, Institute of Mechatronics, Kaunas, Studentu str. 56, Kaunas 51424, Lithuania

2Kaunas University of Technology, Department of Production Engineering, Kaunas, Studentu str. 56, Kaunas 51424, Lithuania

3Kaunas University of Technology, Prof. K. Baršauskas Ultrasound Research Institute, Kaunas, Studentu str. 59, Kaunas 51367, Lithuania

Vid. Proc. Adv. Mater., Volume 3, Article ID 2210379 (2022)

DOI: 10.5185/vpoam.2022.10379

Publication Date (Web): 15 Oct 2023

Copyright © IAAM

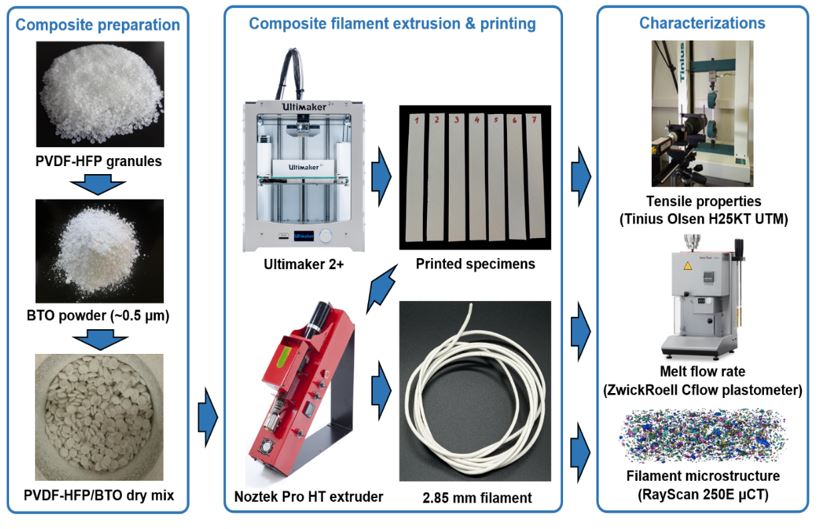

Graphical Abstract

Abstract

This work presents dry processing-based development of thermoplastic polyvinylidene fluoride-co-hexafluoropropylene/barium titanate (PVDF-HFP/BTO) composite, which is a lead-free fluoropolymer-ferrocermic composite (FFC) intended for 3D printing of biocompatible piezoelectric sensors, energy harvesters or other devices. Most of the reported works on FFC fabrication are based on solvent evaporation [1] by using polar aprotic solvents, which are hazardous to human health and environment (e.g. dimethylacetamide (DMAc), N,N-dimethylformamide (DMF) [2]). The use of toxic substances is highly concerning, hence an environmentally friendly solvent-free FFC fabrication method is being developed by using a dry mix of PVDF-HFP granules and BTO powder. The mix undergoes filament extrusion and 3D printing accompanied by mechanical and microstructural characterizations. However, it’s challenging to fabricate a high-quality composite filament with a highly homogeneous distribution of filler particles to ensure the consistent quality of 3D printed structures. Three different composite versions with varying BTO filler content (3, 6, 9 wt%) were fabricated. The granules and powder were mechanically dry mixed and extruded through a single-screw extruder Noztek Pro HT to obtain 2.85 mm filament. The melt mass flow rate (MFR) of the composite filament was determined by using ZwickRoell Cflow plastometer and it was found that there is a marginal reduction in MFR with the increase in filler content. Dispersion and agglomeration of BTO particles in the filament was analysed by means of X-ray computed tomography using RayScan 250E. Distribution of filler particles was observed to be fairly homogeneous without substantial agglomerations that would significantly aggravate the process of fused filament fabrication (e.g., through clogging or discontinuous extrusion of the melt). Ultimaker 2+ was used to print rectangular specimens of different FFC composites and pristine PVDF-HFP copolymer, which were subjected to tensile testing (5 specimens for each test case). The testing was performed in Tinius Olsen H25KT universal testing machine and it was determined that tensile strength and modulus are not significantly affected by the change in filler content. Tensile strength s lightly decreases and tensile modulus slightly increases with higher filler content, but the variation of average values are less than 6% in comparison to pristine PVDF-HFP specimens. Stress-strain curves indicate ductile behaviour for both pristine PVDF-HFP and composite specimens. In all the test cases the nominal strain at break is fluctuating. The findings suggest that the introduction of filler particles into the PVDF-HFP matrix does not lead to the initiation of significant defects and does not negatively influence the mechanical properties of the printed composite. Overall, experimental results indicate that optimized FFC fabrication process and well-adjusted 3D printing process parameters are very important in ensuring consistent quality and mechanical properties of the printed composite. This is a prerequisite for the successful development of additively manufactured flexible and durable piezoelectric sensors and energy harvesters for biomedical or environmental monitoring applications.

Keywords

Additive manufacturing; environmentally safer processing; PVDF-HFP filled with BTO; tensile testing; X-ray microtomography.

Acknowledgement

This research was funded by grant No. S-MIP-17-89 from the Research Council of Lithuania (Project acronym: FLEXYMECH-3DP).

References

- Pei, H., Xie, Y., Xiong, Y. et.al. A novel polarization-free 3D printing strategy for fabrication of poly (Vinylidene fluoride) based nanocomposite piezoelectric energy harvester. Compos. Part B Eng. 2021, 225.

- Li, M. et.al. Controlling the microstructure of poly(vinylidene-fluoride) (PVDF) thin films for microelectronics. J. Mater. Chem. C, 2013, 1, 7695-7702.

Biography

Gopi Kompelli received his BE degree in Mechanical Engineering from M.V.S.R.E.C, Osmania University, India in 2018, MSc degree in Vehicle Engineering from Kaunas University of Technology, Lithuania in 2020. He did his one-year research internship at National Center for Metallurgical Research (CENIM-CSIC), Spain in 2020, mainly working on 3D modelling, metal additive manufacturing, microstructural characterization, and artificial ageing. Currently, he is pursuing PhD in Mechanical Engineering at the Institute of Mechatronics, KTU. His research interest is on the development of thermoplastic lead-free piezocomposites for 3D printing of bioinspired smart structures for mechanical sensing and energy harvesting applications.

Video Proceedings of Advanced Materials

Upcoming Congress