Video Article Open Access

Assessment of Sustainable Particleboard from Natural Fibers using Starch-Based Green Adhesives

Junidah Lamaming1*, Norani Abd Karim2, Amina Adedoja Owodunni3, Rokiah Hashim3

1Chemical Engineering Program, Faculty of Engineering, Universiti Malaysia Sabah, Kota Kinabalu, Sabah, 88400, Malaysia

2Civil Engineering Department, Politeknik Sultan Salahuddin Abdul Aziz Shah, Shah Alam, Selangor, 40150, Malaysia

3Division of Bioresource Technology, School of Industrial Technology, Universiti Sains Malaysia, Penang, 11800, Malaysia

Vid. Proc. Adv. Mater., Volume 3, Article ID 2210372 (2022)

DOI: 10.5185/vpoam.2022.10372

Publication Date (Web): 27 Nov 2023

Copyright © IAAM

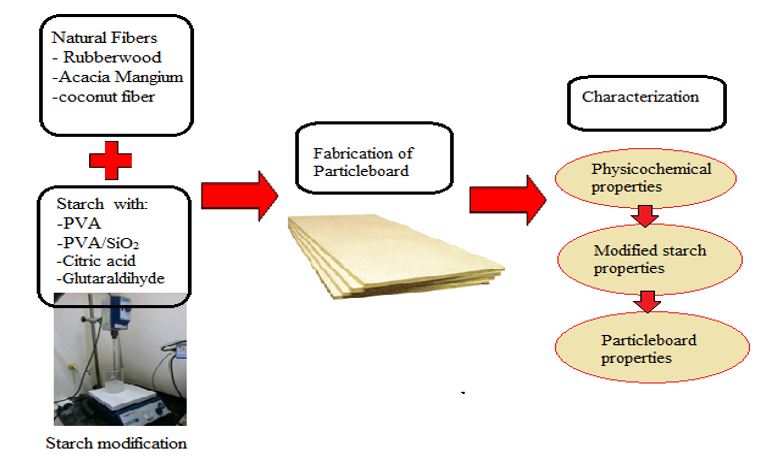

Graphical Abstract

Abstract

Nowadays, combatting the climate change has driven the researchers to find a sustainable solution and materials or sustainable-oriented research. The synthetic materials slowly has been replaced with natural or greener materials. The natural fibers or lignocellulosic materials can be used in the particleboard making. These materials can be blended with other polymers and additives to produce a composite with enhanced physical and mechanical properties that can potentially be used in either indoor or furniture applications. The qualities of the particleboards depend on the modification of the particle geometry, resin levels, board density, and manufacturing processes. The development of particleboard composite made using natural fibers using starch-based adhesives has been compared and evaluated. The natural fibers that were used includes rubberwood, oil palm trunk fibers, and coconut fibers and the starch were commercially wheat starch and potato starch as well as extracted oil palm starch. Further improvement on the adhesive and particleboard performance has been carried out. The modification of starch with polyvinyl alcohol, polyvinyl alcohol with silicone dioxide, citric acid, and glutaraldihyde has been carried out to improve the properties of the produced particleboard by opening the starch granules and developing adhesive bonding. The properties of the modified starch and the particleboard with the addition of the modified starch has been evaluated and compared. Based on the findings, the particleboard made with a modified starch resulted in particleboards with enhanced characteristics when compared to those made from a pure native starch. The mechanical properties of modulus of rupture, modulus of elasticity and internal bonding of the produces particleboards with modified starch as a binder have met the Japanese Industrial Standard (JIS A-5908) for particleboard. The best result showed that the particleboard produced from coconut fiber and citric acid-modified potato starch having a superior properties in terms of dimensional stability and mechanical properties. The findings indicate that the modified starch have the potential to be used as a green binder for particleboard manufacturing.

Keywords

Sustainable particleboard; starch modification; green binder; lignocellulosic materials.

Acknowledgement

We acknowledge Universiti Sains Malaysia for the financial support to carry out the research.

References

- J. Lamaming, N. B. Heng, A. A.Owodunni, S. Z. Lamaming, N.K.A. Khadir, R. Hashim, O. Sulaiman, M.H.M. Kassim, M.H. Hussin, Y. Bustami, M.H.M. Amini, S. Hiziroglu, Composite Part B, 2020, 183, 10773.

- A.A.Owodunni, J. Lamaming R. Hashim, O. F. A..Taiwo, M. H. Hussin, M. H. M. Kassim, Y. Bustami, O. Sulaiman, M.H.M. Amini, S. Hiziroglu, Polymer Composites, 2020, 1-13.

- A.A. Owodunni, J. Lamaming R. Hashim, O. F. A..Taiwo, M. H. Hussin, M. H. M. Kassim, Y. Bustami, O. Sulaiman, M.H.M. Amini, S. Hiziroglu, BioResources, 2020, 15(2), 2279-2292.

- N.A. Karim, J. Lamaming, M. Yusof, R. Hashim, O. Sulaiman, S. Hiziroglu, W.N.A.W. Nadhari, K.M. Salleh, O.F. Taiwo, Journal of Building Engineering, 2020, 29, 101151.

Video Proceedings of Advanced Materials

Upcoming Congress