Video Article Open Access

Clay can help cure cancer: A Dense Gas Approach for Drug Encapsulation in a Nanoclay

Sekar Harikrishnan*, Chau Chun Beh, Neil R. Foster

WA School of Mines: MECE, Curtin University, Perth, 6102, Western Australia

Vid. Proc. Adv. Mater., Volume 3, Article ID 2210371 (2022)

DOI: 10.5185/vpoam.2022.10371

Publication Date (Web): 12 Apr 2023

Copyright © IAAM

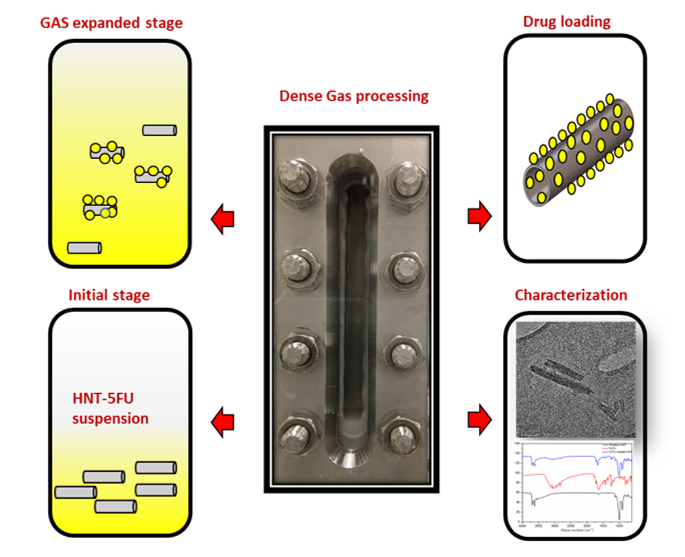

Graphical Abstract

Abstract

Halloysite nanoclays (HNT) are naturally occurring aluminosilicates belonging to the kaolin group. They have a high length-to-diameter ratio and a cylindrical morphology with the inner lumen. The biocompatibility, high surface area, cytocompatibility, and adsorption capacity makes HNT a suitable carrier for many active pharmaceutical ingredients (APIs). Currently, the loading of APIs onto HNT is performed through mechanical methods. These methods are less scalable and require copious quantities of chemicals and solvents. Alternatively, dense gas processing can be used to load APIs into HNT in a greener way. Dense gas processing encompasses advanced eco-friendly formulation techniques employing subcritical and supercritical carbon-dioxide, suitable for producing pharmaceutical formulations. They are scalable, consume less or no harmful chemicals and solvents, and produce less or no toxic residue. In this work, the encapsulation of 5-Fluorouracil (5FU), a principle drug for colorectal cancer treatment, onto HNT was performed using a conventional mechanical process and two dense gas processes. The Gas Antisolvent (GAS) process and novel Atomized rapid injection for solvent extraction (ARISE) process were employed to encapsulate 5FU in HNT. The comparison in effective loading between the conventional and dense gas methods are reported in this study. The HNT-5 FU suspension was expanded with the inclusion of dense CO2 (120 bar, and 110 bar, 25 °C) inside a pressure chamber, and the drug loading was determined for different HNT-5FU mass ratios. Thermogravimetric analysis, Scanning Electron Microscopy, Transmission Electron Microscopy, and X-ray diffraction analysis were performed to characterize the product. The results revealed a high loading of 43% achieved with the GAS process, followed by 17.5 % in ARISE. At the same time, mechanical loading reached only 4.5% loading capacity. The effectiveness of the dense gas processing in encapsulating 5FU in HNT is superior to mechanical loading, opening new routes to produce micro/nano-drug delivery systems suitable for large scale production.

Keywords

Dense gas process, Halloysite nanotubes, 5-Fluorouracil, Active pharmaceutical ingredient, Drug delivery,

Acknowledgement

This research is partially supported by the Australian Government through the Australian Research Council’s Linkage and Discovery Projects funding schemes, and from Curtin University.

Biography

Dr. Sekar Harikrishnan is a chemical engineer and a pharmaceutical nanotechnologist by profession. He completed his PhD in drug nano formulation in Chemical Engineering at Curtin University, Perth, Western Australia. His research focus is on dense gas processing of active pharmaceutical ingredients, specifically focusing on drug encapsulation using various dense gas techniques for targeted drug delivery in colon cancer therapy. He has over a decade of experience in the field of Nanomaterials, MEMS, and Microfluidics Lab-on-a-chip device. His expertise also includes designing and fabricating biomedical MEMS and Microfluidic devices for nanoparticle manipulation and targeted drug delivery systems.

Video Proceedings of Advanced Materials

Upcoming Congress