Video Article Open Access

Applied Research Regarding the Evolution of the Superficial Layer of a Non-Conventionally Treated Steel Subjected to Wear Tests

Carmen - Penelopi Papadatu

Dunarea de jos University, Galati, 800080, Romania

Vid. Proc. Adv. Mater., Volume 3, Article ID 2210357 (2022)

DOI: 10.5185/vpoam.2022.10357

Publication Date (Web): 04 Mar 2023

Copyright © IAAM

Graphical Abstract

Abstract

It was considered a Plasma nitriding applied after a non-conventional treatment realized in magnetic field to a steel used in industry, have been studied in this paper. It has been demonstrated that the energy of the magnetic field intervenes in the balance of the global power of the phase transformations in solid state altering the thermodynamics, kinetics and the mechanisms of processes, the structures and some properties of the steel. The plasma nitriding plant used was the INI 150 Type, made by the Institute of Radiation Physics and Technology in collaboration with the "Electrotechnics" Enterprise and the Nuclear Apparatus (ICEFIZ) from Romania and was destined for technological research, but can also be used for industrial nitriding of small pieces. INI 150 plant was based on the physical phenomenon of a double cathode at plasma (ion) nitriding.

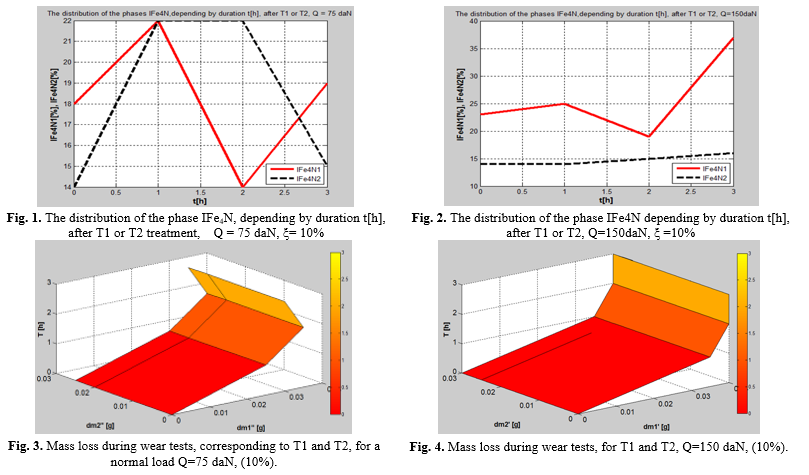

After treatments, the samples have been tested using an Amsler stand for wear tests (dry friction) and the diffractometric analysis completed this study.

Some subjects will be discussed during the presentation how would it be: Considerations regarding the evolution of the concept plasma/ion nitriding, Glow discharge in the case of Plasma nitriding, an Experimental part with researches results, Diffractometric aspects, Phases distribution (IFe4N; IFe3N) in the superficial layer after nonconventional treatment and plasma nitriding process. Due to friction wear tests on Amsler machine, it was possible to study the depth distribution of the Fe3N and Fe4N phases in the superficial layer. The distribution of Fe3N and Fe4N phases on the plasma nitrided layer is uneven, which demonstrates that, no matter how careful we are, the nitriding process does not flow uniformly, being influenced by several factors, especially the nature of the nitrided material. It’s important to be remarked the importance of the nonconventional treatment in magnetic field applied before plasma nitriding, because after the thermo-magnetic treatment applied basically, the hardness of the steel increased with 40% in the case of the non-conventional treatments T2 (alternative current - magnetic field) and the micro-hardness of the superficial layer of steel increased with approx. 25% after plasma nitriding applied after the thermo-magnetic treatment. This evolution depends on the treatment regime applied, comparing to the classic treatment applied.

Keywords

Plasma nitriding, thermo-magnetic treatment, wear tests, superficial layer, steel.

Acknowledgement

The tests have been made in the following laboratories:

- Dunarea de Jos University laboratory, Faculty of Engineering, Dep. Mechanical Engineering.

- Uzinsider Engineering S.A (S.C. I.C.P.P.A.M.-S.A.), Research Institute from Galati, Romania.

References

- C. P . Papadatu, PhD. Thesis, Dunarea de Jos University, Galati , 2005, 145.

- P. Cavaliere, A. Perrone, A. Silvello, Engineering Science and Technology, 2016, 19, 292.

- Kosta-Krämer, Borsa D M at al. Physical Review B 69, published by The American Physical Society, 2004, 144402-1.

- C.P. Papadatu, IOP Conference Series: Materials Science and Engineering, 2017, 174, 01201. DOI:10.1088/1757-899X/174/1/012014.

- https://www.slideshare.net/elquseooso/industrial-plasma-engineering-vol-1

- C P. Papadatu, Possibilities to improve the quality of some steels used in the metallurgical industry, “Dunarea de Jos” University Publishing Foundation, Galati, Romania, ISBN: 978-973-627-371-1, 2006.

- C. P. Papadatu, A. Sandu, M. Bordei, G. Sandu, Study on the Influence of the Treatment in Magnetic Field on the Nitrided Layer in Plasma, Revista de Chimie, 2017, 68, 675- 679, WOS: 000400732400009.

Biography

Work experience: Author and co-author of more than 60 publications: 3 scientific books and 3 courses books – as a unic author, scientific articles indexed in Web of Science (17) or BDI, conferences and seminar papers books, specialty items Materials Engineering, Economics and Environment, published in the country and abroad. Currently, is Associate Professor at "Dunarea de Jos" University, Galati, Romania, Member of the Research Center "Materials and Environmental Quality". Member of the Romanian Association of Tribology (ART) since 2003. Since 2016, she is a member of the Editorial Board of International Multilingual Journal of Science and Technology. Head of Cultural Department of Greek Community from Galati, Romania, between 1993-2008. Languages: English (B2), French and a little Greek language. Technical skills: Achievements in the field of unconventional treatments in a magnetic field, applied to steels used in metallurgy, good results obtained in the field, good communication capacity, competent training.

Video Proceedings of Advanced Materials

Upcoming Congress