Video Article Open Access

Influence of NbC Addition in Aluminum Alloy A380 on Microstructure at Semi-Solid Processing Temperature

Bruno Edu Arendarchuck#, Luciano Augusto Lourençato*, Alexia Wan Der Haagen, Hipolito Domingo Carvajal Fals

Federal University of Technology – Paraná, Ponta Grossa, 84017-220, Brazil

Vid. Proc. Adv. Mater., Volume 3, Article ID 2210356 (2022)

DOI: 10.5185/vpoam.2022.10356

Publication Date (Web): 09 Apr 2023

Copyright © IAAM

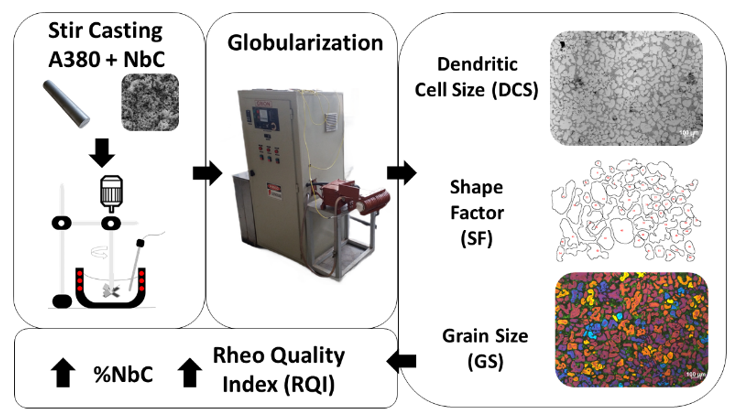

Graphical Abstract

Abstract

The semi-solid processing is a promising technique used to fabricate parts minimizing manufacturing steps of post preparation and a reduction of casting defects. Globular structure is the key in this process, characteristicachieved with the partial meltingmaterial to temperaturesbetween solidus and liquidus. In this process, the Al-Si alloysare common material. However, with the recent increase in industry requirements, aluminum matrix composites (AMC) are studied and shown as an excellent alternative to supply the lack of material properties. Several researches were done to evaluate themechanical, tribological and thermal properties of the composites. In this sense, the aim of this work is evaluated the microstructure quality of the aluminum matrix composite with different NbC concentration after semi-solid treatment.In this work, 0 wt%, 5wt% 10wt% and 15wt% of micron-sized NbCpowder,was used as a reinforcement to fabricate a composite with the A380 alloy melted at 750°C, also grain refiner Al5Ti1B, Sr modifier and Mg wetting agent were added to molten. The stir casting process with 400 rpm for 5 min was used to homogenizethe carbides, and promote the shear in the microstructure. Finally, the composite was poured in steel molds and cooled in air until room temperature. The globularization heat treatment was performed with 562°C, which represents 60% solid fraction, the samples were maintained 90s, then cooled in water. Microstructural formationwas analyzed byoptical microscopeunder conventional and polarized light and scanning electron microscope (SEM). The dendritic cell size (DCS), grain size (GS), shape factor (SF) and rheo quality index (RQI) was used to analyze the morphology. The results show a generally reduction of GS and DCS parameters with the higher amount of NbC. Globularization heat treatment promote a coalescence and coarsening of the as-cast structure, mostly in the reinforcement material. Probably, due to effect of the stir process and particles addition the AMC with NbC shows more globular microstructure when compared with non-reinforced alloy. Although the tendency to promote reduction in grain size with increase in NbC content, the composite with 10wt% show a better number of SFand RQI parameters.

Keywords

Aluminum matrix composite, NbC; semi solid treatment; microstructure.

Acknowledgement

The authors would like to thank the Graduate program (DIRPPG) from Technological Federal University of Paraná (UTFPR). CNPq/Araucaria Foundation for aid in promotion. The CBMM to supply the NbC powder. José Roberto de Campos for building the stir casting system and, Coordination for the Improvement of Higher Education Personnel - Brazil (CAPES) - Financing Code 001, for providing financial support for this study.

References

- A. K. Tuli, P. Singh, S. Das, D. P. Mondal, J. P. Shakya, Sådhanå, 2021, 46,219.

- E. J. Zoqui, L. V. Torres, Materials Research, 2010, 13(3), 305-318.

- P. Das, P. Dutta, Trans Indian Inst Met, 2021, 74(5), 1241-1251.

- J.P.G. Ferreira, L.A. Lourençato, A.S. Roca, H.D.C. Fals, Metall Mater Trans A., 2020, 51, 6421-6431.

- YS Yi, RF Li, ZY Xie, Y. Meng, S. Sugiyama, Vacuum, 2018, 154, 177-185.

Biography

Bruno Edu Arendarchuck is a master's degree student in Mechanical Engineering, at the Federal Technological University of Paraná – UTFPR, Ponta Grossa, Brazil. He received a graduation degree with academic honor diploma from the same university in Mechanical Fabrication. He is interested in aluminum alloys, composite materials and semi solid processing.

Video Proceedings of Advanced Materials

Upcoming Congress