Video Article Open Access

CVD Synthesis of Carbon Nanomaterials for Wearable Protection

Devika Chauhan*, Ashley Kubley, Henry B. Spitz, Mark Schulz

University of Cincinnati, Cincinnati, 45219, USA

Vid. Proc. Adv. Mater., Volume 3, Article ID 2208347 (2022)

DOI: 10.5185/vpoam.2022.08347

Publication Date (Web): 04 Mar 2023

Copyright © IAAM

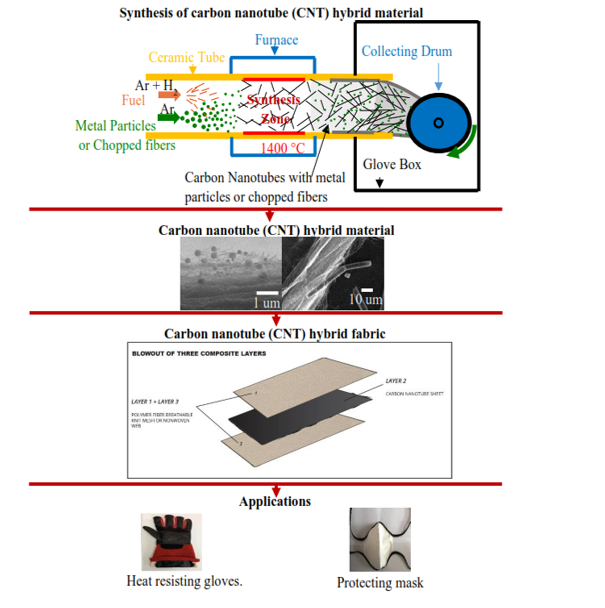

Graphical Abstract

Abstract

Since the discovery of carbon nanotubes (CNTs), they have been a vast research field. The extraordinary properties of CNTs have enabled the integration of CNTs in supercapacitors, patch antennas, and fiber-reinforced composite applications [1,2], to mention a few among the different industrial, commercial, and defense applications. Synthesis of carbon nanotubes (CNTs) by the floating catalyst chemical vapor deposition (FC-CVD) method is apt to meet the demands of the growing field of CNT applications [3,4], among other CNT synthesis methods. Carbon nanotubes are produced using different synthesis methods and usually have reasonable properties. However, achieving the extraordinary properties of single-wall carbon nanotubes is challenging when integrated into macroscopic CNT sheets. To improve their properties in macro-structure form, CNTs can be combined with other nanoparticles and microfibers, which enable them to enhance their properties at the macroscopic level [5]. Different methods exist to integrate metals into CNT sheets and yarn, such as sputtering, electrolysis, physical vapor deposition, and plasma functionalization. All the mentioned methods are two-step processes. This work uses a single-step in situ method to integrate metal and non-metals in the CNT sheet. We propose an in situ integration of CNTs with nanoparticles (NPs) and microfibers to form CNT hybrid material with new/improved properties and lower cost using the floating catalyst CVD method. Various metal, ceramic, and chemical compounds can be used to synthesize the CNT hybrid material. The nanoparticles or the nanofibers are introduced inside the CNT synthesis reactor with a particle feeder and fuel injector systems. The injected nanoparticles or the nanofibers integrate into the macroscopic web of CNTs right in the reactor during the synthesis process. The synthesized flexible CNT hybrid fabric can be used for clothing, filters, and other textile applications. This paper gives an overview of methods of forming various CNT hybrid materials and discusses several applications.

Keywords

Carbon nanotube (CNT); FC-CVD; CNT-hybrid fabric; nanomaterials, nanoparticles.

Acknowledgement

This research study was supported by the National Institute for Occupational Safety and Health through the Pilot Research Project Training Program of the University of Cincinnati Education and Research Center Grant #T42OH008432.

References

- Y. Song et al., Proc. of the American Society for Composites: 31st Technical Conf., 2016.

- D. Chauhan et al., in Proc. of SPIE, 2017, 10172.

- G. Hou et al., Materials & Design, 2017, 132, 112-118.

- G. Hou et al., in Nanotube Superfiber Materials, William Andrew Publishing, 2019, 573-601.

- D. Chauhan et al., J. Text. Sci. Fash. Technol., 2019, 1.

Biography

Devika Chauhan received her Ph.D. in Mechanical Engineering at the University of Cincinnati, following her master’s degree in Aerospace Engineering in 2018. Her research focuses on the CVD synthesis of carbon nanotubes and their integration into novel wearable applications. Experienced in nanomaterial characterization using SEM, EDS, Raman, XPS, XRD, and TGA. Upgraded the CVD reactor to improve operational safety and operational cost. She led 2 NIOSH pilot projects for early career researchers as a PI, co-authored 2 patents, filed 2 invention disclosures, and published multiple journal papers and book chapters.

Video Proceedings of Advanced Materials

Upcoming Congress