Video Article Open Access

Using 4D X-ray Imaging to Develop Durable Materials for Fuel Cells

Erik Kjeang1,*, Yadvinder Singh1, Dilip Ramani1, Francesco P. Orfino1, Monica Dutta2

1Fuel Cell Research Laboratory (FCReL), Simon Fraser University, Surrey, BC, V3T0A3, Canada

2Ballard Power Systems, Burnaby, BC, V5J5J8, Canada

Vid. Proc. Adv. Mater., Volume 3, Article ID 2208342 (2022)

DOI: 10.5185/vpoam.2022.08342

Publication Date (Web): 12 Dec 2022

Copyright © IAAM

Graphical Abstract

Abstract

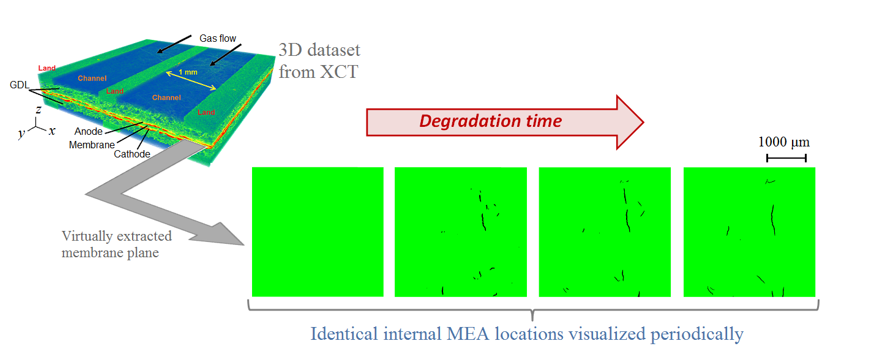

Fuel cell electric vehicles powered by hydrogen offer zero emissions while maintaining the driving performance and range of conventional vehicles. Given the present emissions reduction targets for the transportation sector, the global interest in hydrogen fuel cells for heavy duty vehicles is growing rapidly, as they provide a scalable solution for vehicles with high energy requirements that are otherwise difficult to electrify. However, the fuel cell durability requirements for heavy duty bus, rail, and truck applications are three or four times greater than for light duty passenger vehicles, which poses a significant challenge for fuel cell developers. The research conducted at Simon Fraser University’s Fuel Cell Research Laboratory (fcrel.ca) addresses this challenge in close collaboration with the fuel cell industry cluster in the Metro Vancouver region and international partners. Our research focuses on advancing the state-of-the-art material durability of the membrane electrode assembly (MEA), which is the heart of the fuel cell where the electrochemical reactions take place. In the present talk, I will demonstrate visualization guided fuel cell membrane durability improvements accomplished by tuning the design and fabrication of the membrane electrode assembly. This research leverages a specialized methodology developed by our group for in-situ X-ray computed tomography (XCT) visualization of miniaturized fuel cells subjected to accelerated stress testing. Given its non-invasive nature, the XCT methodology enables unique experimental workflows for 4D in-situ visualization by periodic, 3D identical-location imaging of fuel cells as a function of degradation time [1]. Results obtained from post-processed 4D image sets are used to determine the failure mode, root cause of degradation, and other influential factors throughout the progression of a given degradation process [2]. Knowledge gained from such experiments are subsequently used to develop mitigation strategies for durability improvement, which are then demonstrated and evaluated by repeat testing of aptly modified MEA designs. Specific examples will be given for improved mechanical [3], chemical [4], and chemo-mechanical [5] membrane durability.

Keywords

Fuel cell; hydrogen; durability; membrane electrode assembly.

Acknowledgement

Funding for this research was provided by the Natural Sciences and Engineering Research Council of Canada, Automotive Partnership Canada, Canada Foundation for Innovation, British Columbia Knowledge Development Fund, Western Economic Diversification Canada, Canada Research Chairs, and Ballard Power Systems.

References

- White, R.T., Wu, A., Najm, M., Orfino, F.P., Dutta, Monica., Kjeang, E., Journal of Power Sources, 2017, 350, 94-102.

- Singh, Y., White, R.T., Najm, M., Haddow, T., Pan, V., Orfino, F.P., Dutta, M., Kjeang, E., Journal of Power Sources, 2019, 412, 224-237.

- Singh, Y., White, R., Najm, M., Boswell, A., Orfino, F., Dutta, M., Kjeang, E., Journal of The Electrochemical Society, 2021, 168, 034521.

- Ramani, D., Singh, Y., White, R., Haddow, T., Wegener, M., Orfino, F., Ghassemzadeh, L., Dutta, M., Kjeang, E., Electrochimica Acta, 2021, 380, 138194.

- Chen Y., Singh Y., Ramani, D., Orfino, F.P., Dutta, M., Kjeang, E., Journal of Power Sources, 2022, 520, 230674.

Biography

Erik Kjeang is a Professor in Mechatronic Systems Engineering at Simon Fraser University (SFU) in Vancouver, Canada and Canada Research Chair in Fuel Cell Science and Technology Development. Dr. Kjeang obtained a Ph.D. in Mechanical Engineering from the University of Victoria, Canada and an M.Sc. in Energy Engineering from Umea University, Sweden. Prior to joining SFU, Dr. Kjeang worked as a research engineer at Ballard Power Systems. He has 18 years of experience with fuel cell research, focusing on electrode and cell design. Dr. Kjeang is also a recognized expert on fuel cell durability and recently contributed technology for enhancing and predicting membrane lifetime in fuel cell buses in collaboration with Ballard. His lab at SFU features Canada’s sole facility for multi-length scale X-ray tomography, which is optimal for visualization of electrochemical cells. He has raised more than $28M in funding and authored 130 peer reviewed journal articles and 6 patents.

Video Proceedings of Advanced Materials

Upcoming Congress