Video Article Open Access

Carbon Nanotube Active Textiles Development

Mark Schulz*, Ashley Kubley, Megha Chitranshi, Myoung Ok Kim, David Mast, Devika Chauhan, Vianessa Ng, Amit Bhattacharya, Brooke Brandewie, Stephanie Wood, Vesselin Shanov, Anuptha Pujari

University of Cincinnati, Cincinnati, Ohio 45211, USA

Vid. Proc. Adv. Mater., Volume 3, Article ID 2208340 (2022)

DOI: 10.5185/vpoam.2022.08340

Publication Date (Web): 23 Dec 2022

Copyright © IAAM

Graphical Abstract

Abstract

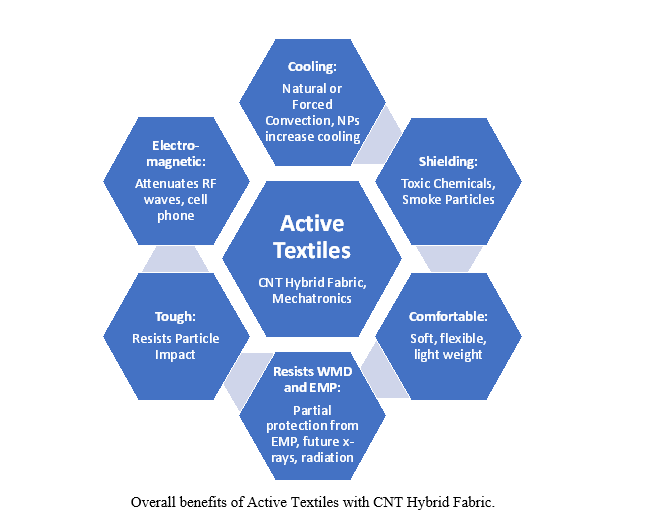

Personal protective apparel design has not changed fundamentally in the past few decades and has been based on using passive fabrics. This lecture discusses Active Textiles (AT) development and the design of new personal protective apparel that can improve wearer safety and performance. AT integrate composited fabric, advanced garment manufacturing, high-capacity small batteries, miniaturized fans and controllers, flexible sensors, and multifunctional carbon nanotube (CNT) hybrid fabric [1-4] to provide increased performance and safety that cannot be achieved using conventional personal protective apparel. AT are manufactured by layering thin CNT fabric with other high-performance fabric to provide specialized properties customized for the application. Hybrid CNT fabric can incorporate nanoparticles (NPs) into the fabric during the high temperature synthesis process. CNT hybrid material is customizable to provide features that woven and nonwoven fabrics have individually offered. To provide good contact with the body, stretch in the AT apparel is provided through an auxetic architecture that increases the surface area of the fabric, provides isotropic stretch, and increases circulation of air using forced convection. CNT fabric is nonwoven and is manufactured in a continuous scalable process. AT incorporate a power source, electronics, and nonwoven CNT fabric into textile materials and apparel. AT provide two main advantages: (1) Cooling- Protection from Environmental and Metabolic Heat; (2) Shielding- Providing flame resistance, preventing toxic gases and particles from reaching the skin, and EMI shielding. This lecture gives an overview of the design and synthesis of Carbon Nanotube Hybrid fabric and its possible future use in specific textile applications.

Keywords

Carbon Nanotube; hybrid fabric; active textiles; nanoparticles.

Acknowledgement

This research was partially supported by the National Institute for Occupational Safety and Health Pilot Research Project Training Program of the University of Cincinnati Education and Research Center Grant #T42/OH008432.

References

- Patent Pending: Methods of Manufacturing Carbon Nanotube (CNT) Hybrid Sheet and Yarn by Gas Phase Assembly, and CNT-Hybrid Materials, M. Schulz, V. Ng, G. Hou, others, application #: PCT/US2018/019427, February 2018.

- Chapter 12, Smart Textiles and Wearable Technology Innovation with Carbon Nanotube Technology by Ashley Kubley, Devika Chauhan, Sathya Narayan Kanakaraj, Vesselin Shanov, Chenhao Xu, Rui Chen, Vianessa Ng, Greg Bell, Prasoon Verma, Xiaoda Hou, Megha Chitranshi, Anuptha Pujari, Mark J Schulz, in Nanotube Superfiber Materials, Science, Manufacturing, Commercialization, 2nd Edition, edited by M. Schulz, V. Shanov, J. Yin, M. Cahay, Elsevier Jan. 2019.

- Mark J. Schulz, Vesselin Shanov, John Yin, Marc Cahay, editors, Nanotube Superfiber Materials, Science, Manufacturing, Commercialization, 2nd Edition, Elsevier, March 2019.

- Devika Chauhan, Chenhao Xu, Daniel Chen, Ashley Kubley, BrookeBrandewie, Guangfeng Hou, Weifeng Li, Vianessa Ng, Massoud Rabiee, Marc Cahay, Woo Kyun Kim, Sumeet Chaudhary, Khwaja Moinuddin, Michael Paine, Richard Kleismit, David Mast, Surendra Devarakonda, SangYoung Son, Mark J. Schulz, Vesselin N. Shanov, Introduction to Carbon Nanotube Hybrid Textiles, Journal of Textile Science & Fashion Technology, January, 2019, ISSN: 2641-192X DOI: 10.33552/JTSFT.2019.01.000525 https://irispublishers.com/jtsft/, open access journal.

Biography

Mark J. Schulz is a Professor of Mechanical and Materials Engineering at the University of Cincinnati and Co-director of UC Nanoworld Laboratories. The goal of Nanoworld is to integrate nanotech into university-wide curricula, to interest students to go to graduate school, and to invent new smart and nano materials and devices. Nanoworld collaborates with faculty members from multiple disciplines to solve problems that are intractable for one group alone. Nanoworld focuses on solving high reaching interdisciplinary problems while also teaching innovation to students. Mark teaches the course Introduction to Smart Structures that engages students in learning and thinking across disciplines.

Video Proceedings of Advanced Materials

Upcoming Congress