Video Article Open Access

Development and Implementation of Accelerated Bridge Construction Techniques using Ultra-High Performance Concrete and Fiber-Reinforced Polymer Bars

Khaled Sennah

Toronto Metropolitan University (Formerly Ryerson University), Toronto, M5B 2K3, Canada

Vid. Proc. Adv. Mater., Volume 3, Article ID 2206337 (2022)

DOI: 10.5185/vpoam.2022.06337

Publication Date (Web): 22 Dec 2022

Copyright © IAAM

Graphical Abstract

Abstract

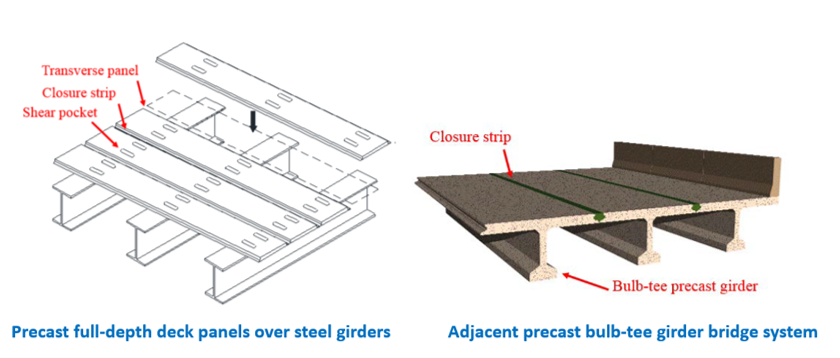

The use of prefabricated elements and systems in accelerated bridge construction (ABC) has recently been the subject of much attention and interest amongst bridge jurisdictions in North America as a way of improving bridge construction and replacement of deteriorated bridges. Through mass production of the materials, the repeated use of forms, and reduction of on-site construction time and labor by concentrating the construction effort in a fabrication facility rather than at the bridge site, significant economic benefits can be achieved. Issues related to work zone safety and traffic disruptions are also a major concern. A full-lane closure is very costly on busy urban highways because of the significant economic impact on commercial and industrial activities. As a result, prefabricated bridge technology is seen as a potential solution to many of these issues. Prefabricated elements and systems can be quickly assembled and could reduce design efforts, reduce the impact on the environment in the vicinity of the site, and minimize the delays and lane closure time and inconvenience to the traveling public, saving time and taxpayers’ money. Even at a higher initial cost, the use of prefabricated systems on bridges subjected to a high volume of traffic may be justified because excessive lane closure times can be avoided. This lecture presents the current state-of-the-art approach to the use of innovative prefabricated systems and elements in modern bridge construction. Dr. Sennah’s research team developed 4 moment-transferring connections and 3 intermittent bolted connections between prefabricated bulb-tee girders that can be used to connect precast prestressed bulb-tee girders to accelerate bridge superstructure replacement, thus avoiding traffic lane closure and traffic disruption. Such joint details incorporated epoxy-coated steel bars and high-strength grouting materials. Then, 12 actual-size precast bridge panels were constructed and tested to collapse to evaluate their structural behavior and load-carrying capacity. Two of the tested connection details were recently used in Moose Creek Bridge and Beaverton Creek bridge replacement in Ontario. Moreover, Dr. Sennah’s research team developed ultra-high performance fiber reinforced concrete (UHPC) for bridge applications. He extended this research by incorporating non-corrosive glass fiber reinforced polymer (GFRP) bars and UHPC as filling material in the longitudinal joints and transverse joints of precast deck panels for sustainable construction for applications in bridges in Ontario. His research team developed a few UHPC-filled, GFRP-reinforced, closure strips between precast deck panels connected longitudinally or transversely. Actual-size precast deck panels supported over twin-steel girders were tested under fatigue loading and static loading to collapse to justify the design. One of the developed UHPC-filled joints between precast deck panels was first implemented in the Elgin Road Underpass, hwy 401 in Ontario, Canada, in 2019. Dr. Sennah’s research team extended this research to the development of design standards of UHPC-filled, GFRP-reinforced, shear keys between adjacent precast box beams to eliminate issues with deteriorated joints in similar existing bridge types. Such design standards for this bridge system and joints were developed based on structural analysis as well as experimental testing to the collapse of actual-size joints. It should be noted that such design standards were incorporated in the 2019 edition of the Canadian Highway Bridge Design Code and implemented in a few Ontario bridges. The presentation will go through the recently developed, and tested to collapse, post-tensioned box girder that was entirely built using UHPC and then implemented in a few China bridges.

Keywords

Sustainable construction, bridges, prefabricated concrete, Fiber-reinforced polymers, FRP, Ultra-high performance concrete (UHPC), design standards.

Acknowledgement

The financial support and in-kind contributions of the following companies and agencies are greatly appreciated: Pultrall Inc., V-Rod Canada Inc., Shoeck Canada Inc., Natural Science and Engineering Research Council of Canada (NSERC Engage, NSERC Discovery), Ontario Centres of Excellence, Voucher for Innovation program (OCE-VIP), Highway Infrastructure Innovation Funding Program of Ontario Ministry of Transportation (MTO-HIIF), Lafarge Canada Inc.

References

- Khalafalla, I.; Sennah, K.; Ultimate and Fatigue Responses of Sand-Coated GFRP-Reinforced, UHPC-Filled, Field-Cast Deck Joints in Slab-On-Girder Bridges, ACI Special Publication (ACI-SP), American Concrete Institute, 2022, In press.

- Su, J.; Ma, X.; Chen, B.; Sennah, K.; Full-scale bending test and parametric study on a 30-m span prestressed ultra-high performance concrete box girder. Journal of Advances in Structural Engineering. https://doi.org/10.1177/1369433219894244, 2019, pp. 1-14.

- Hamoda, A.; Hossain, A.; Sennah, K.; Shoukry, M.; Mahmoud, Z.; Behaviour of Composite High-Performance Concrete Slab-on-Steel I-beams Subjected to Static Hogging Moment. Journal of Engineering Structures, Elsevier, 2017, 140 (1), 51-65.

- Sayed Ahmed, M.; Sennah, K.; Ultimate and Fatigue Responses of UHPFRC-filled, Transverse Angle-joint in Full-depth, GFRP-reinforced, Precast Bridge Deck Panels. Proceedings of the 33rd Annual International Bridge Conference, MD, USA, 2016, pp 1-10.

- Sennah, K.; Afefy, H.; Development, and Study of Deck Joints in Prefabricated Concrete Bulb-Tee Bridge Girders: Conceptual Design. Journal of Bridge Structures, Design, Assessment and Construction, 2015, 11, 33-53.

Biography

Khaled Sennah is a Professor of Structural Engineering at the Civil Engineering Department at Toronto Metropolitan University (formerly Ryerson University), Toronto, Canada. Dr. Sennah’s core area of expertise includes the design, evaluation, and rehabilitation of bridges on which he has more than 260 publications and supervised over 75 graduate students. He has demonstrated numerous evidence of impact and contribution to the economical design and sustainable construction that led to field applications and standards. Dr. Sennah’s research achievements have been recognized by international awards such as the 1999 Arthur Wellington Prize for best journal paper in transportation-related infrastructure and the 2002 State-of-the-Art in Civil Engineering award for the best journal paper, both from the American Society for Civil Engineers, ASCE. Also, he received the 1998 and 2020 P.L. Pratley Award for best paper in bridge engineering and the 2013 A.B. Sanderson Award for “Outstanding Contributions by a Civil Engineer to the Development and Practice of Structural Engineering in Canada,” all from the Canadian Society for Civil Engineering. In recognition of his long-term achievements, he was elected Fellow of the Canadian Society for Civil Engineering (CSCE) in 2011, Fellow of the Engineering Institute of Canada (EIC) in 2016, and Fellow of the Canadian Academy of Engineering (CAE) in 2017. He is a member of a few Canadian Standard Association’s Technical Subcommittees for the development of the Canadian Highway Bridge Design Code. Dr. Sennah has a long history of significant contributions to the Canadian Society for Civil Engineering (CSCE) through committee membership, membership and chairing of scientific committees of conferences, Chairing International conferences and chairing CSCE Structures Division and others. He is currently an Associate Editor for the Canadian Journal for Civil Engineering and an Editorial Board member of ASCE Journal of Composites for Construction. He is also the Co-chair of the 11th International Conference on Short and Medium Span Bridges to be held in Toronto in July 2022.

Video Proceedings of Advanced Materials

Upcoming Congress