Video Article Open Access

Synthesis and Thermomechanical Behavior of SiC/Si Compounds Derived from Wood Waste

M.L. Benavides-Salinas*, D.L. Mayta-Ponce, F.A. Cuzziramos-Gutiérrez, G.P. Rodríguez-Guillén, F.A. Huamán-Mamani

Universidad Católica San Pablo, Arequipa, Peru

Vid. Proc. Adv. Mater., Volume 3, Article ID 2203274 (2022)

DOI: 10.5185/vpoam.2022.3274

Publication Date (Web): 12 Sep 2022

Copyright © IAAM

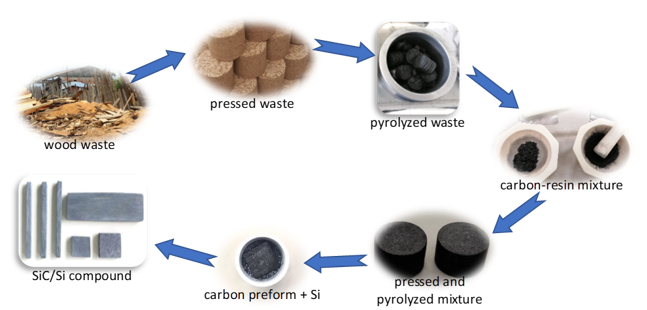

Graphical Abstract

Abstract

The traditional method of manufacturing SiC compounds is associated with a serious environmental problem, mainly due to the need for large amounts of energy (generally derived from oil) to reach processing temperatures (typically above 2500 ºC) [1,2]. In addition, the chemical reaction that gives rise to the formation of SiC has CO and CO2 as by-products. Therefore, in this work an alternative method to manufacture SiC/Si composites using waste from the wood industry as the main raw material was developed. SiC/Si composites were fabricated by infiltration of molten silicon into carbon preforms at 1500 °C. The carbon preforms were obtained by pyrolysis (in an inert Ar atmosphere) of four types of resin-carbon mixtures. The carbon used in the mixtures was obtained by pyrolysis of sawdust powder.

The mechanical and thermomechanical behavior in uniaxial compression was studied at a constant compression rate of 0.05 mm/min at different temperatures (ambient, 1100 °C and 1400 °C). The maximum resistance values found were in the range of 58 and 384 MPa, while the Young's modulus values were between 40 and 120 GPa. The porosity found in the materials was between 1 and 4%. Finally, the fabricated compounds presented a homogeneous microstructure of interconnected silicon carbide in gray contrast and dispersed and unconnected whitish phases of uniformly distributed silicon.

Keywords

Thermomechanical behaviour; SiC/Si compounds; wood waste; silicon carbide; mechanical properties.

Acknowledgement

This work was financed by CONCYTEC - FONDECYT within the framework of call E063-2020-01-BM with contract N° 002-2020-FONDECYT-BM and was executed in the laboratories of the Universidad Católica San Pablo.

References

- Li, F., Liu, J., Huang, X., Zhang, G., “Porous Ultra-High Temperature Ceramics: Preparation, Structure and Properties”, J. of the Chin. Ceram. Soc., 2018, 46(12), 1669-1684.

- Jianwei Song, Chaoji Chen, Shuze Zhu, Mingwei Zhu, Jiaqi Dai, Upamanyu Ray, Yiju Li, Yudi Kuang, Yongfeng Li, Nelson Quispe, Yonggang Yao, Amy Gong, Ulrich H. Leiste, Hugh A. Bruck, J. Y. Zhu, Azhar Vellore, Heng Li, Marilyn L. Minus, Zheng Jia, Ashlie Martini, Teng Li, Liangbing Hu “Processing bulk natural wood into a high-performance structural material” Nat., 2018, 554, 224.

Biography

Miranda L. Benavides-Salinas is a Bachelor of Materials Engineering. Thesis student in the Materials Science and Technology research group (CITEM) of the San Pablo Catholic University. Research lines: composite materials, sustainability in materials.

Video Proceedings of Advanced Materials

Upcoming Congress