Video Article Open Access

Investigation the Effect of Calcium Carbide Waste as A Partial Replacement of Cement in Sandcrete Blocks

Humphrey Danso*, Eric Narteh Quarcoo

Akenten Appiah-Menka University of Skills Training and Entrepreneurial Development, P. O. Box 122, Kumasi, Ghana

Vid. Proc. Adv. Mater., Volume 3, Article ID 2203201 (2022)

DOI: 10.5185/vpoam.2022.03201

Publication Date (Web): 13 Sep 2022

Copyright © IAAM

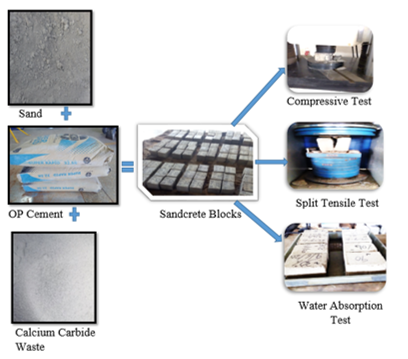

Graphical Abstract

Abstract

Cement production in 2018 amounted to some 2.17 million metric tons in China alone [1]. According to Danso et. al., [2,3], the production of Portland cement (PC) contributes significantly to anthropogenic CO2 emissions in the atmosphere. In order to mitigate the harmful effects of cement on the environment, this study determined the properties of Calcium Carbide Waste (CCW) as replacement of Ordinary Portland Cement (OPC) in sandcrete blocks. OPC was replaced by CCW at 0,10,20,30,40,50 and 90 percent. Mixed ratio 1:6 and a water cement ratio of 0.4 were used. 195 blocks, measuring 100 mm × 100 mm × 135 mm, were prepared and tested for compressive strength, tensile strength, water absorption and density after 7, 14, 28 and 56 days of curing. Results of sandcrete block compressive strength, apart from 90% replacement of CCW, the replacement of 10%, 20%, 30%, 40% and 50% at age 21 were above the minimum compressive strength of 2.8 N/mm2 recommended by the Ghana Standard Authority (GS297, 2003). Similar trend was recorded by the tensile strength test result. The average density of the blocks at day 21 were 2107.619 kg/m3, 2083.095 kg/m3, 2035.238 kg/m3, 2030.476 kg/m3, 2005.952 kg/m3, 1982. 857 kg/m3 and 1851.190 kg/m3 at 0%, 10%, 20%, 30%, 40%, 50% and 90% CCW placement of cement, respectively. The absorption value increases gradually with the percentage rise in the CCW content. However, the best results were obtained at 10% to 40% replacement of cement at 28-days of curing, which met the standard requirement. The study concluded that the calcium carbide waste is viable as partial replacement of cement in sandcrete blocks as it obtained satisfactory results at 14 to 28 days of curing.

Keywords

Calcium carbide waste; cement; sandcrete blocks.

References

- Garside, M.; Major countries in worldwide cement production 2010-2020; Statista International, 2020.

- Danso, H.; Martinson, B.; Ali, M.; Mant, C.; Performance characteristics of enhanced soil blocks: a quantitative review; Building Research & Information, 2015, 43(2), 253-262.

- Danso, H.; Boateng, I.; Quality of Type I Portland Cement from Ghana and UK. Civil and Environmental Research, 2015, 7(1), 38-47.

Biography

Humphrey Danso is a highly motivated individual with construction technology and education background. He is currently a Senior Lecturer, a Consultant and a Researcher in Construction Technology and General Education. He is currently the Head of Department at the Department of Construction and Wood Technology Education at the Akenten Appiah-Menka University of Skills Training and Entrepreneurial Development, Ghana. He has twenty-two (22) years of working experience in both pre-tertiary and tertiary education in Ghana, Russia, the United Kingdom and Australia. He completed his PhD in Civil Engineering at the University of Portsmouth, United Kingdom in 2016. Humphrey possesses excellent communication and writing skills, interpretation and analytic skills, and fluent in written and oral English. This is evident in his over Sixty (60) international journal articles publication and international conference presentations.

Video Proceedings of Advanced Materials

Upcoming Congress