Video Article Open Access

Mechanism of Ti and Mg Based Grain Refinement in Steels

Robert Tuttle

Department of Engineering, Design, Manufacturing, and Management Systems, Western Michigan University, Kalamazoo, MI,49008-5336, USA

Vid. Proc. Adv. Mater., Volume 2, Article ID 2111247 (2021)

DOI: 10.5185/vpoam.2021.11247

Publication Date (Web): 22 Jul 2022

Copyright © IAAM

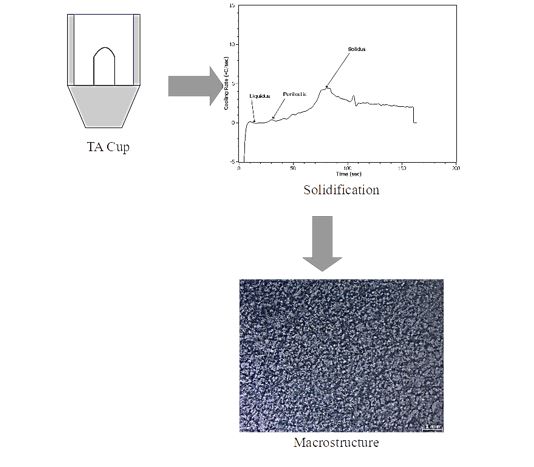

Graphical Abstract

Abstract

Research on solidification-based routes to grain refine steels in their as-cast state have examined titanium and titanium-magnesium additions. These routes are thought to form Ti(C,N) particles that act as heterogeneous nuclei for δ-ferrite. However, Ti(C,N) formation in steels can occur at the end of solidification where they are known to act as grain growth inhibitors. The research presented employed a novel thermal analysis system for steels with ASTM A781 keel block castings to examine both the solidification and properties of 1030 and HY100 with these additions. The thermal analysis system detected and measured solidification reactions. Tensile testing and metallographic analysis were conducted on the test castings to help correlate properties and macrostructure with the solidification reaction changes. Refinement occurred in some Ti or Mg+Ti additions in both steels. However, the liquidus temperatures did not increase as expected. Measurement of the peritectic temperature in these alloys also found no discernible difference from baseline heats. TiN particles were observed in both steels and MgO inclusions were found to act as nuclei for the TiN particles. Refinement of the structure occurred in 1030 to a significant degree while it was less pronounced in HY100. This correlated with the resulting mechanical properties with those heats with the finer structures having better properties. The lack of change in liquidus despite the presence of TiN particles in the steels appears to support the theory they are acting as grain growth inhibitors instead of heterogeneous nuclei. TiN particles appear to form in the late stages of solidification where they cannot act as nuclei; however, they can still effectively pin austenite grain boundaries and prevent grain growth which results in the finer structure observed. This correlates well with existing data and industrial experience on titanium based microalloy steels. Mg additions did appear to reduce the size of TiN particles in 1030. It appears they may act as nuclei for TiN particles and assist in reducing the size of these particles. This finer TiN particle size ensures they are not detrimental to mechanical properties.

Keywords

Grain refinement; steel; thermal analysis; heterogeneous nucleation.

Acknowledgement

This work was funded through award number N000141712766 from the Office of Naval Research. MeltLab Systems also contributed their knowledge of thermal analysis which assisted in cooling curve interpretation. Tyler Schramski, Hunter Towalski, Kaylee Konwinwki, and Isaak Portice’s assistance in conducting the experiments are also duly appreciated.

References

- Tuttle, R.; Transactions of the American Foundry Society, 2020, 128, 241.

- Tuttle, R.; Proceedings of AISTech 2020, 2020, 1, 129.

- Tuttle, R.; Archives of Foundry Engineering, 2019, 19, 83.

- Kapadia, H.; Tuttle, R.; Transactions of the American Foundry Society, 2019, 127, 357.

- Park, J.; Calphad, 2011, 35, 455.

Video Proceedings of Advanced Materials

Upcoming Congress