Video Article Open Access

Mechanical Behavior of Beta-Type Titanium Alloy Lattice Structures Fabricated by Additive Manufacturing

Lai-Chang Zhang1,*, Yujing Liu2

1Edith Cowan University, Perth, WA6027, Australia

2Changsha University of Science and Technology, Changsha, 410114, China

Vid. Proc. Adv. Mater., Volume 2, Article ID 2111246 (2021)

DOI: 10.5185/vpoam.2021.11246

Publication Date (Web): 22 Jul 2022

Copyright © IAAM

Graphical Abstract

Abstract

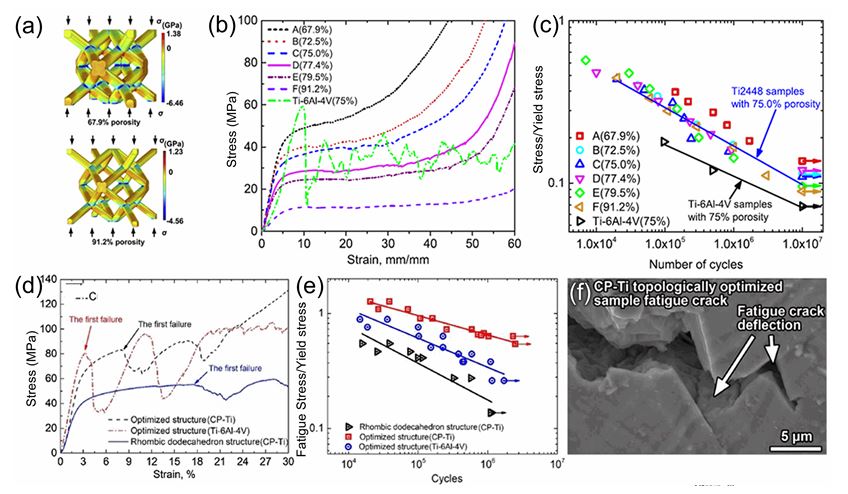

Beta-type titanium porous structures are a new class of solution for implants because they offer excellent combination of high strength and low Young’s modulus. This presentation studies the influence of porosity variation in 3D printing (via electron beam melting (EBM)-produced and selective laser melting (SLM)) produced beta-type titanium alloy samples on the mechanical properties including super-elastic property, Young’s modulus, compression strength, energy absorption and fatigue properties. Compared with Ti-6Al-4V samples, the beta-type titanium porous samples exhibit a higher normalized fatigue strength owing to super-elastic property, greater plastic zone ahead of the fatigue crack tip and the crack deflection behaviour. Stress distribution results, obtained by finite element methods, coupled with the investigation of the slip bands generated have been used to reveal the plasticity mechanism and local stress concentrations for each structure. The topology optimized structure exhibits the best balance of bending and buckling stress with a high elastic energy absorption, a low Young’s modulus and a high compression strength.

Keywords

Additive manufacturing; titanium alloys; lattice structure; mechanical behavior; mechanical properties.

Acknowledgement

The authors would like to acknowledge the financial supports provided by the Australian Research Council through Discovery Projects (DP11010653, DP130103592). The authors are grateful to Shujun Li, Yulin Hao, Tim Sercombe for their collaborations.

References

- Chen, L. Y.; Liang, S. X.; Liu, Y.; Zhang, L. C.; Materials Science and Engineering R: Reports, 2022, XX, 100648.

- Liu, Y. J.; Li, S. J.; Wang, H. L.; Hou, W. T.; Hao, Y. L.; Yang, R.; Sercombe, T. B.; Zhang, L. C.; Acta Materialia, 2016, 113, 56.

- Liu, Y. J.; Wang, H. L.; Li, S. J.; Wang, S. G.; Wang, W. J.; Hou, W. T.; Hao, Y. L.; Yang, R.; Zhang, L.C.; Acta Materialia, 2017, 126, 58.

- Liu, Y. J.; Li, S. J.; Zhang, L. C.; Hao, Y. L.; Sercombe, T. B.; Scripta Materialia, 2018, 153, 99.

- Liu, Y. J.; Ren, D. C.; Li, S. J.; Wang, H.; Zhang, L. C.; Sercombe, T. B.; Additive Manufacturing, 2020, 32, 101060.

Video Proceedings of Advanced Materials

Upcoming Congress