Video Article Open Access

New Insight into Vertical Topographical Selective Deposition of Tantalum Oxide Ta2O5 by Morphological Analyses

Gauthier Lefevre1,*, Moustapha Jaffal1, Taguhi Yeghoyan1, Rémy Gassilloud2, Nicolas Posseme2, Christophe Vallee1,4, Marceline Bonvalot1, 3

1University Grenoble Alpes, CNRS, CEA/LETI-Minatec, Grenoble INP, LTM, F-38054 Grenoble-France

2CEA-LETI, Minatec Campus, F-38054 Grenoble, France

3University of Tsukuba, department of Pure and Applied Physics, Tsukuba Ibaraki 305 8571 Japan

4Colleges of Nanoscale Science & Engineering, SUNY Polytechnic Institute, Albany, New York, USA

Vid. Proc. Adv. Mater., Volume 2, Article ID 2110235 (2021)

DOI: 10.5185/vpoam.2021.10235

Publication Date (Web): 21 Jul 2022

Copyright © IAAM

Graphical Abstract

Abstract

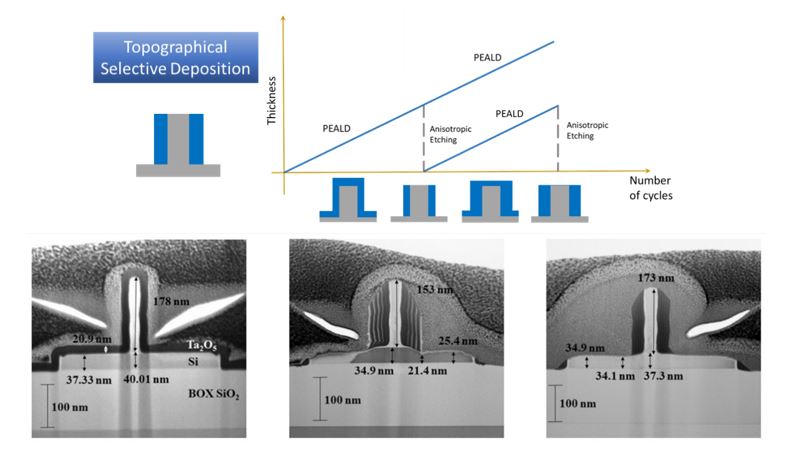

In the race of electronic miniaturization, current top-down processes are reaching their limits and new bottom-up techniques are evolving rapidly [1]. Avoiding numerous and costly fabrication process steps and placement errors, Area Selective Deposition (ASD) is attracting a lot of attention, even though implementation, settings and shortcomings of this innovative technique remain challenging at the moment [2]. When dealing with 3D features, selective deposition is named Topographical Selective Deposition (TSD) and can lead to the fabrication of vertical-only coating of 3D substrates. This TSD is of particular interest for potential applications such as direct gap filling or spacer definition for instance.

In this work, we develop a Ta2O5 TSD process using super-cycles alternating Plasma-Enhanced Atomic Layer Deposition (PEALD) steps and two different approaches of anisotropic etching steps: quasi-Atomic Layer Etching (ALE) and argon ion sputtering [3]. Nanocharacterization of obtained results is presented and allows an accurate analysis of modifications in the Ta2O5 vertical film deposited with various ASD approaches. Results clearly show differences in terms of thickness, texture and chemical element composition. More specifically, one approach including quasi-ALE step shows better results with limited damages of the 3D features.

Therefore, morphological analysis of thin films helped to choose better selective deposition processes, as a pathway towards industrial applications of ASD.

Keywords

Nanocharacterization; topographical selective deposition; plasma-enhanced atomic layer deposition.

Acknowledgement

We acknowledge the financial support of LabEx Minos and this work was partly supported by the french RENATECH network.

References

- A.J.M. Mackus, M.J.M. Merkx, W.M.M. Kessels, Chem. Mater., 2019, 31, 2.

- C. Vallée, M. Bonvalot, S. Belahcen, T. Yeghoyan, M. Jaffal, R. Vallat, A. Chaker, G. Lefèvre, S. David, A. Bsiesy, N. Possémé, R. Gassilloud, and A. Granier, J. Vac. Sci. Technol. A, 2020, 38, 033007.

- M. Jaffal, T. Yeghoyan, G. Lefèvre, R. Gassilloud, N. Possémé, C. Vallée, and M. Bonvalot, Journal of Vacuum Science & Technology A., 2021, 39, 030402.

Video Proceedings of Advanced Materials

Upcoming Congress