Video Article Open Access

Electrospun Core-shell Nanofibers for Protection against Corrosion

I. C. Vladu*, L. Balc, M. Sinnabell, L. Rafailovic

Centre of Electrochemical Surface Technology (CEST), Viktor Kaplan Strasse 2, Wiener Neustadt, 2700, Austria

Vid. Proc. Adv. Mater., Volume 2, Article ID 2108222 (2021)

DOI: 10.5185/vpoam.2021.08222

Publication Date (Web): 17 May 2022

Copyright © IAAM

Graphical Abstract

Abstract

Aluminium is an active metal and its resistance to corrosion depends on its capability to form protective oxide films. Currently, the most widely used strategy is based on the application of anodization processes. Anodized layers with additional sealing are already on the industrial market and provide enhanced corrosion protection, but there is place for improvements. An innovative way of counteracting corrosion is proposed: electrospun core-shell nanofibers.

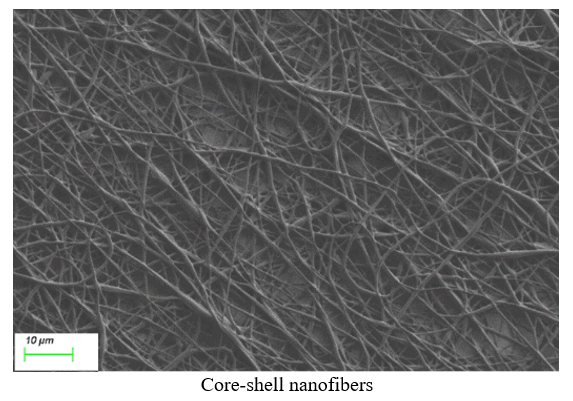

Core-shell polyurethane/oil nanofibers were produced using the coaxial electrospinning set-up. Optimization of the electrospinning parameters was done in order to achieve the formation of beads free nanofibers. The distance between the co-axial needle and the collector was tailored between 80 mm and 180 mm. Flow rate for the oil was also tailored from 0.01ml/h to 0.07ml/h. Co-axial electrospinning experiments were performed at ambient temperature.

Electrospun nanofiber mats were placed either directly on the Al substrates after removing the native oxide (degreasing and pickling) either in between two commercially available coating layers. The morphology of the electrospun nanofibers was observed by means of scanning electron microscopy (SEM). The core-shell nanofibers layer thickness as measured by focused ion beam (FIB) was tailored between 1 and 20 µm as a function of deposition time. Surface wettability of various surfaces (nanofibers, nanofibers incorporated in the coating) was investigated by means of contact angel measurements. Adhesion of the commercially available coating with and without core-shell nanofibers was measured by performing cross cuts test according to ISO 2409. IR and Raman measurements were performed on PU and PU/oil core-shell nanofibers for comparison. Additionally, electrochemical impedance spectroscopy (EIS) measurements in NaCl solution and open circuit potential measurements were performed to characterize the performance of the core-shell nanofibers against corrosion.

Keywords

Core-shell nanofibers; corrosion; coatings.

Acknowledgement

Authors acknowledge the funding authorities FFG, LubRes project, 861043.

Video Proceedings of Advanced Materials

Upcoming Congress