Video Article Open Access

Robust Stimuli-Responsive Polymer Systems by Physical Design

Syamal S. Tallury 1,*, Melissa A. Pasquinelli 2, Kenneth P. Mineart 3, Richard J. Spontak 2

1ExxonMobil Chemical Company, Baytown TX, USA

2North Carolina State University, Raleigh NC, USA

3Bucknell University, Lewisburg PA, USA

Vid. Proc. Adv. Mater., Volume 2, Article ID 2108210 (2021)

DOI: 10.5185/vpoam.2021.08210

Publication Date (Web): 22 Jul 2022

Copyright © IAAM

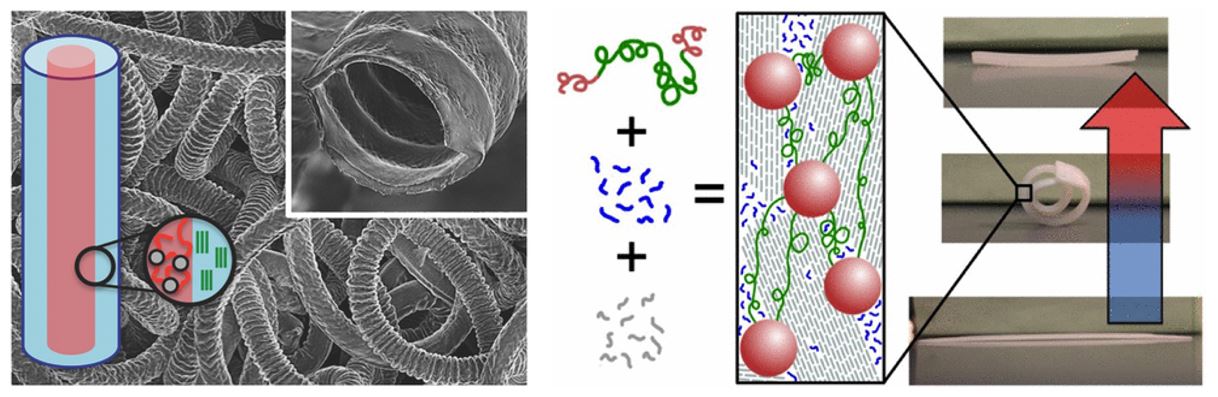

Graphical Abstract

Abstract

Smart polymeric materials are of increasing interest in contemporary technologies due to their low cost, light weight, facile processing, and inherent ability to change properties, shape, and/or size upon exposure to an external stimulus. We demonstrate thermally programmable shape-memory polymers (SMPs), which typically rely on chemistry-specific macromolecules composed of two functional species. While an elastic, network-forming component allows stretched polymer chains to return to their relaxed, entropically stable state, and a switching component affords at least one thermal transition to regulate fixation of a desired metastable strain state and reversion to a previous strain state. In one example of physical design, we depict designer shape-memory materials by combining thermoplastic elastomeric triblock copolymers with a midblock-selective phase-change additive, thereby yielding shape-memory polymer blends (SMPBs). These materials not only exhibit tunable switch points but also controllable recovery kinetics. We highlight the versatility of SMPs and SMPBs through bicomponent spinning [1] and laminate welding for intermediate multishape fabrication and liquid metal inclusion for shape-memory electronics [3]. We further report the nature of the molecular networks and the interfacial interactions in the two polymeric components studied using mesoscale molecular modeling and self-consistent field theory [2].

Keywords

Shape memory; stimuli responsive; polymer networks, block copolymer phase behavior.

Acknowledgement

We thank the support from Nonwoven Institute and NCRC project 10-127.

References

- Tallury, S.S.; Pourdeyhimi, B.; Pasquinelli, M.A.; Spontak, R.J.; Macromolecular Rapid Communications, 2016, 37, 1837.

- Tallury, S.S.; Mineart, K.P.; Woloszczuk, S.; Williams, D.N.; Thompson, R.B.; Pasquinelli, M.A.; Banaszak, M.; Spontak, R.J.; Journal of Chemical Physics, 2014, 141, 121103.

- Mineart, K.P.; Tallury, S.S.; Li, T.; Lee, B.; Spontak, R.J.; Industrial & Engineering Chemistry Research, 2016, 55, 12590.

Biography

Syamal ‘Sam’ Tallury is currently the Product Innovation Manager, Global Chemicals Research, ExxonMobil Chemical, based in Baytown TX. Sam’s work focuses on polymer structure-property relationships spanning wide range of polymeric and polymer based composite materials from thermoplastics (Polypropylene, Vistamaxx™) to elastomers and synthetic oils (Vistalon™ and Spectrasyn™). His expertise is in using experimental and computational modeling techniques to investigate polymer phase behavior and microstructure of materials subjected to various processing and application conditions. Dr. Tallury is a trusted expert in the processing of melt-spun fiber and nonwoven materials that are integral to hygiene, medical and composites applications. He has been working for ExxonMobil since 2013, holding various positions in Research and Technology.

Prior to joining ExxonMobil, he worked as a researcher at the Nonwoven Institute, Raleigh NC and Polymer Morphology Group developing shape memory polymer articles and devices. He obtained his Masters in 2009 and doctorate in Materials Science & Engineering and Fiber & Polymer Science in 2013 involving computational, experimental and data mining tools to understand polymer phase behavior, all from North Carolina State University. Dr. Sam Tallury has co-authored 3 book chapters, 6 patents and 12 peer reviewed articles. He hails from southern India and has obtained his Bachelors of Technology from Osmania University.

Video Proceedings of Advanced Materials

Upcoming Congress