Video Article Open Access

Carbon Hybrid Materials - by Design

Mark Schulz1,*, Vesselin Shanov1, Sung Yong Kim2, David Mast1, Devika Chauhan1, Rui Chen1, Vianessa Ng1, Megha Chitranshi1, Anuptha Pujari1, Ronald Hudepohl1, Ashley Kubley1, Devanathan Anantharaman1, Amit Bhattacharya1, Svitlana Fialkova3, Sergey Yarmolenko3

1University of Cincinnati, Cincinnati, Ohio 45211, USA

2Pukyong National University, Busan 45813, Republic of Korea

3North Carolina A&T State University, Greensboro, North Carolina, 27411, USA

Vid. Proc. Adv. Mater., Volume 2, Article ID 2108206 (2021)

DOI: 10.5185/vpoam.2021.08206

Publication Date (Web): 22 Jul 2022

Copyright © IAAM

Graphical Abstract

Abstract

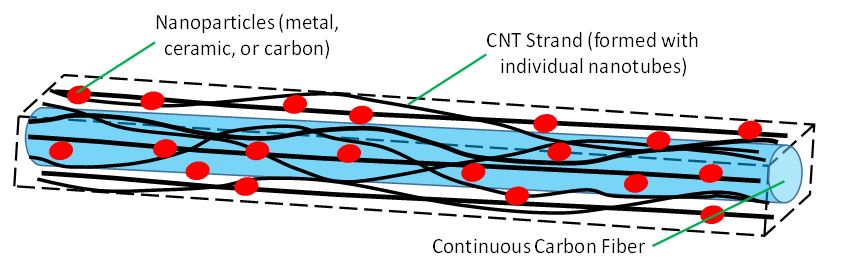

The purpose of Carbon Hybrid Materials (CHM) research is to design and synthesize new materials for critical applications. This lecture gives an overview of the development of CHM which is performed by a large team. The experimental procedure used is to combine different Additive Materials (AM) with Carbon Nanotube (CNT) nonwoven matrix material to form custom hybrid materials. A CNT sock which is web-like assembly of strands composed of individual CNTs is produced in the floating catalyst method. The sock is deposited onto a drum and and acts as a fabric matrix material. Key findings are that it is possible to use the matrix material to form CHM in different practical ways. Nanoparticles (NPs) are integrated within the matrix. The strands and encapsulate the micro-fibers which are in the form of short fibers, continuous fibers. other types of AM can also be used. However, the AM should be small to best integrate with the CNT fabric matrix which is non-woven. Adding NPs into the inlet of the synthesis process is done using a custom designed particle injector that can inject different types of nano and micro particles into the high temperature nanotube synthesis process. NPs and short and continuous fibers can also incorporated into the CNT sock matrix as it is being wound onto a take-up drum in the harvesting box. Solvent which can contain embedded particles or fibers is used to densify the CNT sock. Properties of the CHM produced depend on the AM used. A conclusion is that CHM can be designed to be lightweight and strong in tension, and can form polymer-free composites, electrical conductors and shields, radiation shields, and many other types of customized materials. Composite materials formed using the CNT sock as a matrix material and adding particles or fibers, or both, to the matrix can be an important new material. The CNT sock must completely encapsulate the particle or fiber to have the effect of a matrix material that holds and protects the fiber. Van der Waals forces and entanglement forces are most effective at the nanoscale, thus the AMs must be separated and dispersed when integrated into the CNT sock. Continuous carbon fibers are integrated by winding onto the drum but a flat tow of carbon fibers is needed so that the CNT sock can individually encapsulate the CF. The CHM formed are composite fabrics with no conventional binder or polymer matrix material. Potentially, these polymer-free composites can have modest and tailorable stiffness in bending and would be useful for applications where a polymer matrix is unsuitable. Molecular nanocarbon science has been focused on new forms of carbon and hydrocarbons using organic synthesis. In [1], it is stated that a mixture problem and an unsynthesized problem are holding back the field and “the establishment of new methodologies and techniques for molecular synthesis and structural analysis will remain of vital importance.” Also, “modification of nano-carbons will lead to new fields and applications associated with their unforeseen properties and functions.” This lecture also discusses combining chemically and physically CNT with metals and other carbon and ceramic materials. Adding metals to the nanotube synthesis process has created sheets, spirals and cone shaped carbon forms, and CNT bundles have been “glued” together at their ends with Ag-Cu spheres [2-5]. The CHM method is new and it is unknown what new materials may have properties by design. CHM technology is bringing out new carbon-metal hybrids.

Keywords

Carbon nanotube; fabric matrix; additive materials; nanoparticles; continuous fiber.

Acknowledgement

This research was supported by the NSF ERC EEC-0812348 and the UCTAC Seed Grant under ESP TECH 15-0160. This research study was also partially supported by the National Institute for Occupational Safety and Health Pilot Research Project Training Program of the University of Cincinnati Education and Research Center Grant #T42/OH008432.

References

- Kenichiro Itami, Takehisa Maekawa, Molecular Nanocarbon Science: Present and Past, Nano letters, ACS, 2020, 20, 4718-4720.

- Mark J. Schulz, Vesselin Shanov, John Yin, Marc Cahay, editors, Nanotube Superfiber Materials, Science, Manufacturing, Commercialization, 2nd Edition, Elsevier, March, 2019.

- Mark J. Schulz, Guangfeng Hou, Vianessa Ng, Massoud Rabiee, Marc Cahay, Sumeet Chaudhary, Dustin Lindley, Devika Chauhan, Michael Paine, Dineshwaran Vijayakumar, Chenhao Xu, Zhangzhang Yin, Kevin Haworth, Yijun Liu, Murali Sundaram, Weifeng Li, David Mast, Vesselin N. Shanov; Science to Commercialization of Carbon Nanotube Sheet and Yarn; World Scientific and Engineering Academy and Society, 8th International Conference on Nanotechnology, Cambridge, UK, February 24-26, 2017.

- Guangfeng Hou, Ruitao Su, Anli Wang, Vianessa Ng, Weifeng Li, Yi Song, Lu Zhang, Murali Sundaram, Vesselin Shanov, David Mast, David Lashmore, Mark Schulz, Yijun Liu; The Effect of a Convection Vortex on Sock Formation in the Floating Catalyst Method for Carbon Nanotube Synthesis, Carbon, Volume 102, June 2016, Pages 513–519.

- Devika Chauhan, Chenhao Xu, Daniel Chen, Ashley Kubley, BrookeBrandewie, Guangfeng Hou, Weifeng Li, Vianessa Ng, Massoud Rabiee, Marc Cahay, Woo Kyun Kim, Sumeet Chaudhary, Khwaja Moinuddin, Michael Paine, Richard Kleismit, David Mast, Surendra Devarakonda, SangYoung Son, Mark J. Schulz, Vesselin N. Shanov, Introduction to Carbon Nanotube Hybrid Textiles, Journal of Textile Science & Fashion Technology, January, 2019, ISSN: 2641-192X DOI: 10.33552/JTSFT.2019.01.000525 https://irispublishers.com/jtsft/, open access journal.

Biography

Mark J. Schulz is Professor of Mechanical and Materials Engineering at the University of Cincinnati and is Co-director with Dr. Vesselin Shanov of the Nanoworld Laboratories at the University (https://ceas.uc.edu/research/centers-labs/nanoworld.html). Nanoworld is a large academic laboratory for carbon nanoscale materials research. The strategic goal of the Nanoworld laboratory is to integrate nanotech into university-wide curricula, to interest students to go to graduate school, and to develop new engineering and medical devices based on carbon materials and biodegradable metals. The Nanoworld Lab focuses on societally important and complex problems, and teaching innovation to students. Nanoworld is trailblazing and road mapping innovation, translating the discoveries to industry, and training a next generation workforce that will be in high demand. Mark teaches the Introduction to Smart Structures course. He co-founded the “Nanotechnology Materials and Devices (NMD) Workshop.” The NMD Workshop is organized by the University of Cincinnati, the Air Force Research Laboratory and the University of Dayton Research Institute. Nanotube experts from around the world attend. Mark advised over 70 graduate students. He and his students produced many publications and patents, and conducted many research projects. Mark co-edited four books on nanotechnology. He has a PhD degree in Mechanical Engineering from the State University of New York at Buffalo. Mark collaborates with researchers at other universities (North Carolina A&T SU, the University of Pittsburgh) and industries. He is a fellow of the American Institute for Medical and Biological Engineering and has been a Distinguished Engineering Researcher in the College of Engineering and Applied Sciences.

Video Proceedings of Advanced Materials

Upcoming Congress