Video Article Open Access

A Practical Friction-Based Approach to Modeling Multicomponent Diffusion in Polymeric Systems

John Zielinski1, Brian Hanley2, William Schieser3, Ronald Danner4 and J. Larry Duda4

1Intertek, Allentown, PA 18195, USA

2Air Products and Chemicals, Allentown, PA 18195, USA

3Lehigh University, Bethlehem, PA, 18015, USA

4The Pennsylvania State University, University Park, PA, 16802, USA

Vid. Proc. Adv. Mater., Volume 2, Article ID 2105230 (2021)

DOI: 10.5185/vpoam.2021.05230

Publication Date (Web): 12 Sep 2022

Copyright © IAAM

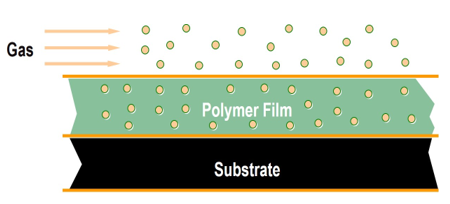

Graphical Abstract

Abstract

Industrial drying and separation technologies are generally based on the molecular transport of multiple components. Analysis of polymer-based processes is particularly challenging since diffusion rates can vary over several orders of magnitude particularly when examined over a broad range of temperature and concentration. In this presentation, a practical means of predicting multicomponent diffusion behaviour from binary self-diffusion and thermodynamic information will be discussed [1-3].The application of the model will be highlighted for two, industrial processes: 1) the devolatilization of polyvinyl alcohol and 2) the drying of a polyvinyl acetate film [4].

Keywords

Diffusion; multicomponent; drying.

Acknowledgement

We extend our thanks to Air Products and Chemicals, Inc for financial support of this work and to numerous colleagues for insightful discussions.

References

- Zielinski, J.M., and Hanley, B.F., AIChE J., 1999, 45 (1), 1-12.

- Palamara, J.E., Zielinski, J.M., Hamedi, M., Duda, J.L., and Danner, R.P., Macromolecules, 2004, 37, 6189-6196.

- Zielinski, J.M., Hamedi, M., Balashova, I.M., and Danner, R.P., Polym Int., 2014, 63: 221–227.

- Price P.E. and Hadj Romdhane, I., AIChE J., 2003, 49(2), 309-322 (2003).

Biography

JOHN M. ZIELINSKI, Allentown, PA 18195, USA

Professional experience

Intertek Allentown (2010-present)

Material properties work team supervisor and sorption laboratory manager

Manage a team of 10 people and $5M of assets to provide paid analytical services, primarily in characterizing polymers, porous media and catalysts. Specialize in experimental method development, modeling and in-depth analysis of unique industrial materials. Cross-selling for other laboratories.

• Collaborated as part of management team and built a business from scratch to $11M in sales in 10 years.

• Crafted customized analytical problem-solving strategies for novel materials or operational troubleshooting.

• Expanded portfolio to include new offerings, e.g., layer analysis and barrier properties of packaging.

• Named Intertek “Engineer of the Year” 2020.

• Expert in diffusion, permeation, equilibrium analyses, thermogravimetric studies and porosity assessment.

• Broad understanding of applying of analytical techniques to solve customer problems including: BET, TGA, DVS, OTR, WVTR, DSC, TMA, DMA, FTIR, XRF, XRD, GC-MS, LC-MS, ICP-OES, and NMR.

• Supported business to maintain a Net Promotor Score (NPS) of approximately 75.

AIR PRODUCTS AND CHEMICALS

1995-2010

Lead Research Engineer

Managed laboratory team of 5 people to characterize materials for multiple divisions, encompassing manufacturing sites and research teams. Collaborated with experts inside and outside the company to provide internal project teams with tailored tests and modeling.

• Created novel testing protocols to support cryogenic and atmospheric gas separation and purification research plans.

• Created a mathematical model for the PVOH manufacturing site to predict drying times.

• Acquired new equipment and testing techniques (e.g., Rubotherm, DPAU) to support strategic business initiatives.

• Supported the development of a variety of products including membranes for gas separation, polyvinylalcohol (PVOH), VAE emulsions, epoxies and polyurethane foams.

• Authored ~50 peer-reviewed journal articles and have contributed to book chapters and an entry in the Encyclopedia of Materials: Science and Technology.

• Collaborated to provide critical data to advance many areas of interest to APCI including:

Kinetic Separations of Gases by Adsorbents at Cryogenic Temperatures

Membrane Technology for Natural Gas Separations

Hydrogen Storage Materials (DOE sponsored – only industrial partner)

Development of Low-k dielectric materials

Improved adsorbents for non-cryogenic production of O2 and large-scale H2 plants

Food Packaging with MAP environments

Production of high-solid latex emulsions with low viscosity

Optimizing drying of PVOH unit to reduce VOC emissions

Other related experience

Johannes Gutenberg Universität Mainz-Max Planck Institute For Polymer Research – Germany

Post-doctoral polymer researcher (SG- AND PFG-NMR, FRS, PCS)

Air products & chemicals, inc.

Research engineer in performance chemicals technology - epoxies

The pennsylvania state university

Doctoral candidate

U.S. Department of energy

Project manager and technical representative in the advanced concepts research division.

Professional Organizations

Adjunct Professor, Department of Chemical Engineering, The Pennsylvania State University, (1996 – 2016)

Industrial and Professional Advisory Council (IPAC), The Pennsylvania State University – Chairman (2010)

Alexander von Humboldt Society of America

American Institute of Chemical Engineers

Alpha Chi Sigma

Education

Post-Doc, Physical Chemistry, Universität Mainz/Max Planck Institut für Polymerforschung, Germany

PhD, Chemical Engineering, The Pennsylvania State University, State College, PA

MS, Chemical Engineering, University of California, Berkeley, CA

BChE, Chemical Engineering and Mathematics, Manhattan College, New York, NY

Video Proceedings of Advanced Materials

Upcoming Congress