Graphical Abstract

Abstract

Polymeric materials have played an increasingly important role in process industry. The membrane technology has developed over more than 50 years from basic research to invention of sophisticated materials which can be tailored for efficient separation of almost any components in a gas mix. This has resulted in demonstration of membrane modules set up at various types of industrial plants where new clean separation technology may replace traditional unit operations using chemicals or expensive cooling units. The challenge is basically that (polymeric) membrane materials must be tailored for achieve optimum separation properties for a given gas mixture. Thus, basic material research goes hand-in-hand with process engineering towards a greener future. The focus for membrane material development today is the valuable contributions this research will have in the fight against the release of climate gases to the atmosphere and likewise for promotion of new green energy sources like biogas and hydrogen for fuel.

In our research group Memfo at NTNU, much of the focus has been on the development of facilitated transport membranes for CO2 capture from various flue gas streams, upgrading of biogas and hydrogen as a energy carrier. A few of the highlights from this research will be highlighted in the presentation.

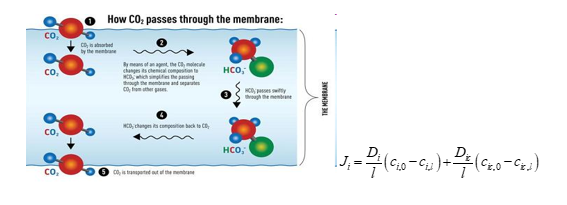

The inspiration is for much of this membrane material development has been, and still is, how membranes work in nature. By studying how our lungs work to separate out the CO2 when we are breathing, we were able to mimic the breathing process and optimize a polyvinylamine material for CO2 capture from the flue gas at coal fired power plants or any industrial plant releasing large volumes of CO2, for instance cement plants. Continuous testing and development over many years, has been necessary to document how this functional material can tolerate various process conditions and potential harmful components in a flue gas stream. Along with this development, and in collaboration with Prof. Spontak and the research institute SINTEF, we also focused on alternative innovative hybrid materials such as using modified POSS® nanoparticles embedded in a polymer.

As in all membrane research measurements of separation properties such as measurements of permeance (especially for CO2), selectivity (CO2/N2) and durability towards harmful components (Sox, NOx) were documented, along with instrumental characterization of the materials such SEM, FTIR, XRD, TGA and DSC.

With respect to alternative energies and a green future, carbon molecular sieve membranes (CMSM) were also developed and studied. These membranes have a large potential for separation related to biogas and natural gas, and separating out H2 from a gas stream.

Keywords

Facilitated transport membranes; CO2-capture; carbon membranes; membranes for Green Technology.

Acknowledgement

The Norwegian Research Council is highly acknowledged for contributions to the many projects referred to in the current presentation.

References

- TJ Kim et al., J. Membrane Sci., 2013, 428, 2018.

- G..Guerrero et al., Membranes, 2018, 8, 28.

- S. Haider, A. Lindbrathen, MB Hägg, Green Energy & Environment, 2016, 1, 222.

Biography

May-Britt has had most of her active career within the academic world, with only a short break for a few years in industry (at that time Statoil, now Equinor). She worked for many years at Telemark University College both as a researcher and Head of Chemical Engineering Department. She holds both her MSc and later Doctor of Technology from the Norwegian University of Science and Technology (previously NTH and now NTNU). From 2001-2021 she worked as professor, the last four years as professor emerita, at the Chemical Engineering Department at NTNU. She has published more than 100 papers in international peer reviewed journals and held numerous presentations at international conferences.

Her focus within research has since 1990 been on membranes for gas separation which then naturally includes both membrane materials (with focus on polymers and carbon molecular sieves), membrane technology and applications. She is an experienced project leader both within basic research and innovation projects in collaboration with industry. Carbon capture in various forms like natural gas sweetening, biogas upgrading and CO2 from flue gases have been in focus. She holds five patents in collaboration with researchers in her group and TTO/NTNU; three on a fixed-site-carrier (FSC) membrane which had been developed to pilot stage and tested with good results when she retired. In 2017 she received the SINTEF/NTNU CCS Award for this research. She has initiated two start-up companies, and was in 2011 nominated (Norwegian Research Council) to female innovator of the year.

When she moved to Oslo 2019, she established a small consultancy company focusing on membrane technology (Hagg Consulting).

Video Proceedings of Advanced Materials

Upcoming Congress