Video Article Open Access

Strain Sensors based on Plasticized Poly(Vinyl Chloride) Nanocomposites

Hatice Aylin Karahan Toprakci1,2,* , Richard J. Spontak3,4 , Tushar K. Ghosh2, #

1Department of Polymer Materials Engineering Yalova University, 77100, Yalova Turkey

2Department of Textile Engineering Chemistry & Science and Fiber & Polymer Science Program North Carolina State University Raleigh, NC 27695, USA

3Department of Materials Science & Engineering North Carolina State University Raleigh, NC 27695, USA

4Department of Chemical & Biomolecular Engineering North Carolina State University Raleigh, NC 27695, USA

Vid. Proc. Adv. Mater., Volume 2, Article ID 2105190 (2021)

DOI: 10.5185/vpoam.2021.05190

Publication Date (Web): 21 Aug 2021

Copyright © IAAM

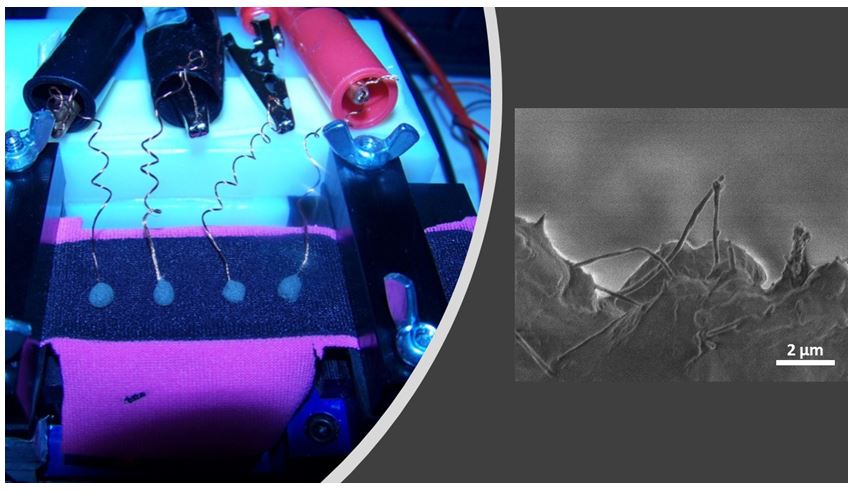

Graphical Abstract

Abstract

Parallel with the developments in the mobile technology and control systems, electronic applications of the polymers have gained significance recently. Polymer based wearable electronics are one the most important reflections of the studies carried out in the last two decades. As known, wearable electronics can be worn by the user and have at least one electrical function. Textiles are one of the most ideal platforms for wearable electronics, since they are deformable, comfortable and lightweight. In addition to these, they can be fabricated in various forms and structures with high efficiency and low cost. Although traditional textiles are used to cover, protect and insulate body from the environment; electronic textiles offer additional functions such as responsive or adaptive behaviour to the environmental stimuli, health monitoring, posture monitoring and so on. In order to perform these functions electronic capabilities are required. In this study, textile based piezoresistive strain sensors were fabricated. Piezoresistive sensors are used to determine the applied strain by monitoring the change in resistance. Textile-based sensors were prepared by using the knitted fabric and traditional printing media known as plastisol. Plastisol is basically plasticized poly(vinyl chloride) (PVC) with flexible structure. Electrical conductivity of the plastisol was achieved by incorporation of carbon nano fibers (CNFs) into the plastisol. In the first step of the study, CNF/PVC composites were fabricated at various CNF concentrations. Percolation behaviour of the nanocomposites was determined and piezoresistive sensing performance of the films were evaluated. Following that, the samples those showed the most stable and high performance were chosen and printed on knitted fabrics. Morphological, electrical and piezoresistive behaviour of the textile-based sensors were evaluated. Morphological analysis showed homogeneous filler dispersion in plastisol matrix and printed nanocomposite conductive layer presented good adhesion to the fabric. The CNF/PVC nanocomposite printed fabrics were found to exhibit significant sensitivity to applied strain and magnitude of sensitivity was found to depend on magnitude of strain and filler concentration [1].

Keywords

Polymer nanocomposites; piezoresistive strain sensors; textile sensors.

Acknowledgement

This work was supported by the U.S. National Science Foundation.

References

- H.A.K. Toprakci, S.K. Kalanadhabhatla, R.J. Spontak, T.K. Ghosh.; Adv. Funct. Mater., 2013, 23 (44), pp. 5536-5542.

Biography

Hatice Aylin Karahan Toprakci was born in Izmir, Turkiye, as a second daughter of Hicran and Erdogan Karahan. She graduated from Afyon Science High School in 1999. She completed her Bachelor of Textile Engineering degree in 2004 at Ege Univeristy. After that she started to work as a research assistant for her Master of Science (M.S.) degree in the same university and graduated in 2007. Following her M.S. in 2007, she worked as a laboratory manager assistant in Gamateks, Turkey. In 2008 she joined North Carolina State University to pursue her Ph.D. in ‘Fiber & Polymer Science’ with a minor in ‘Materials Science & Engineering’.

Video Proceedings of Advanced Materials

Upcoming Congress