Video Article Open Access

Micro- and Nano-Electrochemical Techniques in Corrosion Science Research

Frank Cheng

University of Calgary, Calgary, T2N 1N4, Canada

Vid. Proc. Adv. Mater., Volume 2, Article ID 2105172 (2021)

DOI: 10.5185/vpoam.2021.05172

Publication Date (Web): 29 Jul 2021

Copyright © IAAM

Graphical Abstract

Abstract

Corrosion of metals is electrochemical in nature. Various electrochemical techniques provide one of the most promising methods for corrosion research. These include conventional potentiodynamic polarization, electrochemical impedance spectroscopy (EIS), linear polarization resistance (LPR), etc. However, these measurement techniques suffer from an incapability (or a limited capability) of investigating corrosion reactions occurring at a “small” spatial dimension. In reality, failures of engineering structures are usually associated with localized corrosion occurring at micron or even sub-micron scales. For example, frequent pipeline leaking accidents has been caused by internal pitting corrosion, where corrosion pits are usually at micron scale, especially at the initiation stage.

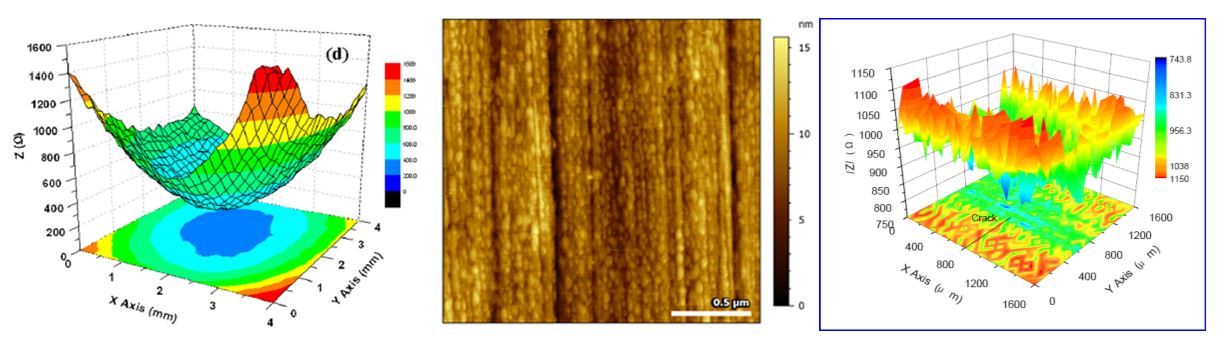

This talk will review the speaker’s research in the last two decades by introducing advanced micro- and nano-electrochemical techniques, i.e., localized EIS (LEIS) and scanning vibrating electrode technique (SVET) and electrochemical atomic force microscopy (ECAFM), in corrosion science research. The novel techniques enable characterization of metallic corrosion and dissolution events at microns and nanoscales, respectively. The working principles of the techniques will be imparted, followed by specific research topics through the implementation of the techniques.

The micro-electrochemical measurement techniques such as LEIS and SVET are built upon electrochemical probes with a high spatial resolution, without compromising the measurement capability. The covered topics include metallurgical micro-electrochemistry, local electrochemical dissolution at crack-tip, and localized corrosion at coating defects. The research established the micro-electrochemical activities of various metallurgical features contained in steels and determined the mechanistic aspects of corrosion pit and crack initiation and propagation. The synergism of stress, corrosion and hydrogen on cracking processes was characterized quantitatively. Moreover, corrosion at coating pinholes was studied to determine the mechanistic change along with specific features of the measured micro-electrochemical signals. The research, at the first time of its kind, studies pipeline steel corrosion at microscopic scales, contributing to a strong knowledge base in the area.

For nanoscale dissolution phenomena, the ECAFM was used to investigate nanoscale features of passive films, and initiation of pitting corrosion under biofilms. The technique is featured of an excellent integration of electrochemical control/measurements with modern surface characterization capability. The research characterized the passive films formed at different polarization potentials and determined mechanistically the protectiveness of the films formed under varied conditions. It also determined the role of microorganism in passivity breakage and pit initiation and growth.

It is anticipated that the talk casts a flash to use modern micro- and nano-electrochemical techniques, enabling us to understand the corrosion phenomenon at a more mechanistic level.

Keywords

Corrosion; metallurgical microelectrochemistry; localized electrochemical impedance spectroscopy; scanning vibrating electrode technique; electrochemical atomic force microscopy.

Acknowledgement

This work was supported by Natural Science and Engineering Research Council (NSERC) of Canada, Canadian Foundation for Innovation (CFI), and the University of Calgary.

References

- Y. Frank Cheng, Nature, 2016, 529, 156.

- Y. Frank Cheng, Stress Corrosion Cracking of Pipelines, John Wiley, Hoboken, NJ, 2013.

- Y. Frank Cheng, Richard Norsworthy, Pipeline Coatings, NACE, Houston, TX, 2017.

Biography

Frank Cheng is a Professor and Canada Research Chair in Pipeline Engineering at the University of Calgary. He is an internationally recognized authority in Corrosion Science and Engineering, and Pipeline Integrity Management. He developed the Metallurgical Micro electrochemistry theory to understand pipeline corrosion at micro- and nanoscales, and thus, at a more mechanistic level. His Mechano-Electrochemical Interaction concept established the stress corrosion thermodynamics and kinetics. Technically, his Multi-Physics Field Coupling Effect Model is being used by industry on defect assessment of pipelines for improved integrity management. Dr. Cheng has authored 3 books and 240+ journal papers. The total citations of his publications exceed 10,920, with a H-index of 66 (Google Scholar). In Scopus, his work has been cited 9,180 times, and the H-index is 61. He is elected Fellow of National Association of Corrosion Engineering (NACE), US, and Institute of Corrosion, UK. He is the recipient of numerous prestigious awards, including 2014 H.H. Uhlig Award and 2021 Technical Achievement Award of NACE, 2015 Shi Chang-Xu Award of Chinese Society for Corrosion and Protection, 2017 Metal Chemistry Award and 2020 Distinguished Materials Scientist Award of Canadian Metallurgy and Materials Society, 2020 Best Research Award of International Research Awards on New Science Inventions, 2015, 2018, 2019 and 2020 Research Achievement Awards of the University of Calgary’s Schulich School of Engineering, and 2010, 2017 and 2018 Teaching Achievement Awards of Schulich School of Engineering. He is serving as the Editor-in-Chief of Journal of Pipeline Science and Engineering (Elsevier). Dr. Cheng obtained a Ph.D. degree in Materials Engineering at the University of Alberta in 2000.

Video Proceedings of Advanced Materials

Upcoming Congress