Video Article Open Access

Designing Chemically Complex Alloys and Composites for Engineering Applications

J. Eckert1,2

1Erich Schmid Institute of Materials Science, Austrian Academy of Sciences, A-8700 Leoben, Austria

2Department of Materials Science, Montanuniversität Leoben, A-8700 Leoben, Austria

Vid. Proc. Adv. Mater., Volume 2, Article ID 202111248 (2021)

DOI: 10.5185/vpoam.2021.11248

Publication Date (Web): 05 May 2022

Copyright © IAAM

Graphical Abstract

Abstract

Metallic materials with tailored properties are crucially important for a variety of structural and functional applications. There is a strong need not only for successful development of new high performance alloys but also for elaborating suitable processing routes enabling control over phase and microstructure selection, and optimization of the related physical and mechanical properties.

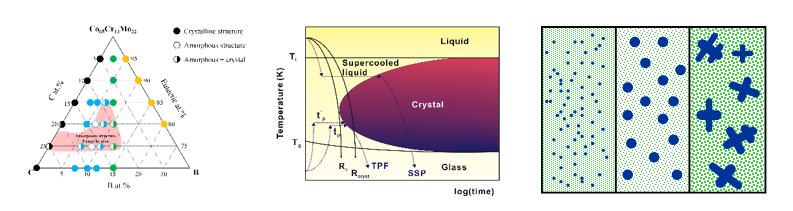

This talk explores the structural diversity that can be achieved in chemically complex materials including amorphous phases, high entropy alloys and multiphase composites developed through a combination of concepts for designing chemically complex alloys and metallic glasses using rapid quenching and annealing or severe plastic deformation for tuning phase formation and microstructure development. The role of length-scale modulation and phase transformation upon heating or loading will be critically assessed with respect to structural stability and mechanical behavior. Examples for changes in deformation mechanism, e.g., from crack-controlled to dislocation-dominated deformation, twinning or cooperative deformation of shear bands and interfacial sliding, will be presented and discussed as ways to control strength, ductility and fracture toughness in a wide range. Besides, also examples for developing novel nanostructured and ultrafine-grained complex materials via composition and process control will be given, attempting to derive guidelines for how to tune the microstructure and properties of non-equiatomic chemically complex alloys with optimized properties.

Examples for the composition tuning, adjustment of processing conditions and process variables employed for synthesis of chemically complex phases with different structures and length-scale modulation will be described and correlated with the resulting phases, microstructures and properties. These techniques include casting, quenching under non-equilibrium conditions as well as thermo-mechanical processing for the synthesis of metastable materials with the desired microstructure and properties. Experimental data for the resulting structures obtained by non-equilibrium processing will be presented for selected amorphous, ultrafine-grained or nanostructured alloys, and the mechanisms responsible for phase and microstructure formation and the related properties will be discussed in order to derive guidelines for optimized alloy design and tailoring of properties.

Keywords

Metastable phases, alloy design, processing, fabrication, property optimization.

Acknowledgement

This work was supported by the ERC Advanced Grant INTELHYB (ERC-2013-ADG-340025).

References

- Kim, J.T.; Hong, S.H.; Park, H.J.; Kim, Y.S.; Suh, J.Y.; Lee, J.K.; Park, J.M.; Maity, T.; Eckert, J.; Kim, K.B.; Scientific Reports, 2017, 7, 39959.

- Kim, J.T.; Hong, S.H.; Kim, Y.S.; Park, H.J.; Maity, T.; Chawake, N.M.; Prashanth, K.G.; Song, K.K.; Wang, W.M.; Eckert, J.; Kim, K.B.; Journal of Non-Crystalline Solids, 2019, 505, 3109.

- Zhang, Z.Q.; Song, K.K.; Guo, S.; Xue, O.S.; Xing, H.; Cao, C.D.; Dai, F.P.; Völker, B.; Hohenwarter, A.; Maity, T.; Chawake, N.; Kim, J.T.; Wang, L.; Kaban, I.; Eckert, J.; Scientific Reports, 2019, 9, 360.

- Zhang, Z.Q.; Song, K.K.; Li, R.; Xue, O.S.; Wu, S.; Yan, D.L.; Li, X.L.; Song, B.; Sarac, B.; Kim, J.T.; Ramasamy, P.; Wang, L.; Eckert, J.; Materials, 2019, 12, 590.

- Kim, J.T.; Hong, S.H.; Park, J.M.; Eckert, J.; Kim, K.B.; Journal of Materials Science & Technology, 2020, 43, 135.

Biography

Jurgen Eckert, is Director of the Erich Schmid Institute (ESI) of Materials Science of the Austrian Academy of Sciences and Head of the Department Materials Physics at Montanuniversität Leoben, Austria and Professor at Dresden University of Technology, Germany. He is coauthor of more than 1100 scientific papers and has 20 patents in the areas of materials science and processing technology. He is member of editorial board of Materials Today Advances. He received several honours and awards such as the Gottfried Wilhelm Leibniz Award of the German Research Foundation, an ERC-Advanced Grant of the European Research Council, the ISMANAM Senior Scientist Award, the Hsun Lee Lecture Award of the Chinese Academy of Sciences, the DGM Georg-Sachs-Prize etc.

Video Proceedings of Advanced Materials

Upcoming Congress