Video Article Open Access

Water-based, Self-Extinguishing Nanocoatings for Fire Protection of Plastics

Jaime Grunlan1,2,3, *, Yu-Chin Li3, Ryan Smith2, Kevin Holder3, Galina Laufer3, Merid Haile3, Thomas Kolibaba2, Simone Lazar2, Marcus Leistner1, Amanda Cain3, Tyler Guin4

1Department of Mechanical Engineering, Texas A&M University, College Station, TX 77843, USA

2Department of Chemistry, Texas A&M University, College Station, TX 77843, USA

3Department of Materials Science and Engineering, Texas A&M University, College Station, TX 77843, USA

4Department of Chemical Engineering, Texas A&M University, College Station, TX 77843, USA

Vid. Proc. Adv. Mater., Volume 2, Article ID 2021-02143 (2021)

DOI: 10.5185/vpoam.2021.02143

Publication Date (Web): 31 Mar 2021

Copyright © IAAM

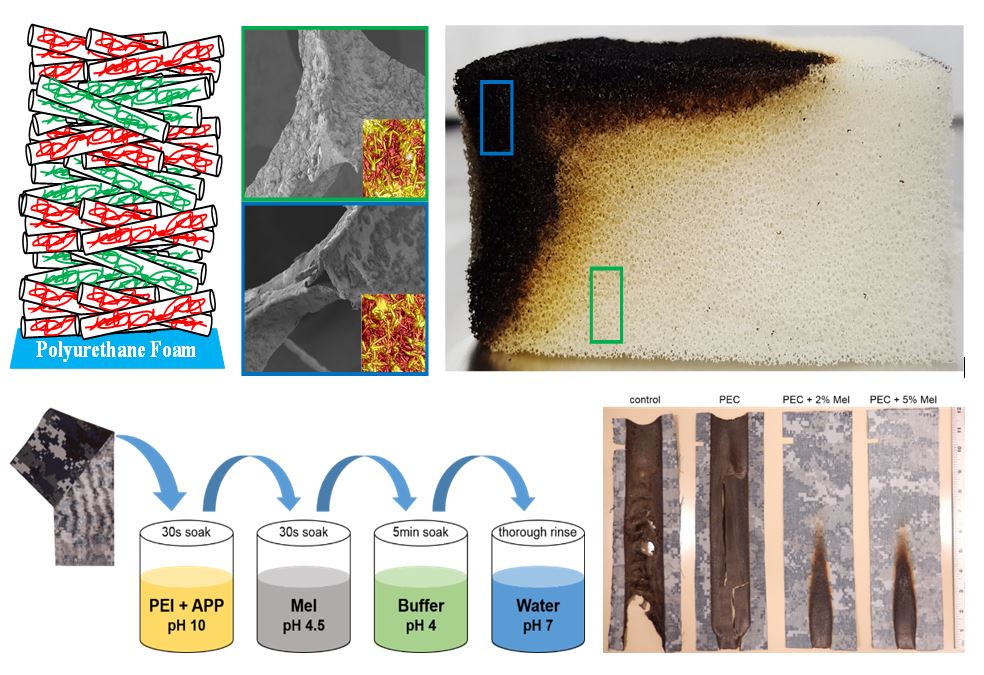

Graphical Abstract

Abstract

In an effort to develop a more environmentally-benign flame retardant for polyurethane foam (PUF), layers of halloysite clay nanotubes (HNT) stabilized by branched polyethylenimine (BPEI) or poly(acrylic acid) (PAA) were deposited from aqueous suspensions to create multilayered nanocomposite coatings. PUF is very flammable and widely used in upholstered furniture throughout the world. Foam treated with five BPEI-HNT/PAA-HNT bilayers (BL), deposited using layer-by-layer (LbL) assembly, was rendered self-extinguishing in open flame testing, as shown in Figure 1. Cone calorimetry reveals that this coating reduces the peak heat release rate (pkHRR) by 62%. Due to the tubular morphology of HNT, small volatile gasses given off during combustion are trapped, so total smoke release (TSR) is reduced by 60%. Infrared spectroscopy suggests this multilayer film survives during combustion, forming a HNT-rich barrier that prevents mass and energy transfer during open flame testing and calorimetry. The significant reductions in pkHRR and TSR, along with the self-extinguishing behavior, indicate that these halloysite-based multilayer films have the potential to greatly improve PUF fire safety. At its core, LbL is a solution deposition technique in which layers of cationic and anionic ingredients are built up via electrostatic attractions in an alternating fashion, but it has the drawback of numerous processing steps. In an effort to more quickly impart flame retardant behavior to blended fabric, and in an environmentally-benign manner, an aqueous polyelectrolyte complex (PEC) was utilized. Blends of cotton with synthetic fibers are widely used for various military and industrial applications. Using chitosan and an insoluble phosphorus source in alternating layers, less than 15 wt% coating is necessary to impart self-extinguishing properties to a polyester-cotton fabric. Immediate self-extinguishment in the vertical flame test and a significant reduction of peak heat release of the fabric are the result of this coating. In an effort to impart flame retardant behavior to fabric using fewer processing steps, a water-soluble polyelectrolyte complex (PEC) was devloped. This nanocoating is comprised of polyethylenimine and poly(sodium phosphate) and imparts self-extinguishing behavior to cotton fabric in just a single coating step. Adding a melamine solution to the coating procedure as a second step renders nylon-cotton blends self-extinguishing. This work demonstrates the ability of a PEC nanocoating to prevent ignition of textiles with few processing steps, relatively low weight gain, and environmentally-benign ingredients. Our flame retardant work has been highlighted in C&EN, ScienceNews, Nature, Smithsonian Magazine, Chemistry World and various scientific news outlets worldwide. For more information, please visit: http://nanocomposites.tamu.edu.

Keywords

Intumescent; flame retardant; environmentally-benign; polyelectrolytes; renewable.

Acknowledgement

Various companies, the Texas A&M Engineering Experiment Station (TEES) and the National Institute of Standards and Technology (NIST) contributed to this work.

References

- S. Lazar, T. J. Kolibaba, J. C. Grunlan, Nature Reviews Materials, 2020, 5, 259.

- T. J. Kolibaba, C.-C. Shih, S. Lazar, B. Tai, J. C. Grunlan, ACS Materials Letters, 2020, 2, 15.

- S. Lazar, F. Carosio, A.-L. Davesne, M. Jimenez, S. Bourbigot, J. C. Grunlan, ACS Applied Materials and Interfaces, 2018, 10, 31686.

- R. J. Smith, K. M. Holder, S. Ruiz, W. Hahn, Y. Song, Y. M. Lvov, J. C. Grunlan, Advanced Functional Materials, 2018, 28, 1703289.

- M. Leistner, M. Haile, S. Rohmer, A. Abu-Odeh, J. C. Grunlan, Polymer Degradation and Stability, 2015, 122, 1.

Biography

Jaime Grunlan is the Linda & Ralph Schmidt ’68 Professor of Mechanical Engineering at Texas A&M University, where he has worked for 16 years. He holds joint appointments in the Department of Materials Science and Engineering and the Department of Chemistry. His research focuses on thermal and transport properties of polymer nanocomposites. He is a world leader in organic thermoelectric materials, gas barrier layers for food and electronics packaging and environmentally-benign flame retardant nanocoatings. Dr. Grunlan is actively working with a number of companies to commercialize these technologies. He holds 14 issued U.S. patents and several EU patents that have been licensed to more than 10 companies. He won the NSF CAREER and 3M Untenured Faculty awards in 2007, Dow 2009 Young Faculty Award, and TEES Senior Faculty Fellow in 2016 for his work in these areas. He has published more than 170 journal papers, with more than 17,000 citations. Dr. Grunlan has graduated 23 PhD students and has mentored more than 50 undergraduate students in his research laboratory. His work has been highlighted in Smithsonian Magazine and the New York Times. He is an Editor of the Journal of Materials Science and serves on the International Advisory Boards for Macromolecular Rapid Communications and Macromolecular Materials and Engineering. In 2018, Prof. Grunlan became a Fellow of the American Society of Mechanical Engineers (ASME) and was awarded a doctorate honoris causa from the University of South Brittany (Lorient, France). In 2019, he became a Senior Member of the National Academy of Inventors (NAI).

Video Proceedings of Advanced Materials

Upcoming Congress