Video Article Open Access

Piezoelectric Materials – A Crossing between The Sensing Electronics and The “Green” Energy

Mariya Aleksandrova

Technical University of Sofia, Department of Microelectronics, Kliment Ohridksi Blvd, 8, Bl. 1, Sofia 1000, Bulgaria

Vid. Proc. Adv. Mater., Volume 2, Article ID 2021-02116 (2021)

DOI: 10.5185/vpoam.2021.02166

Publication Date (Web): 18 Mar 2021

Copyright © IAAM

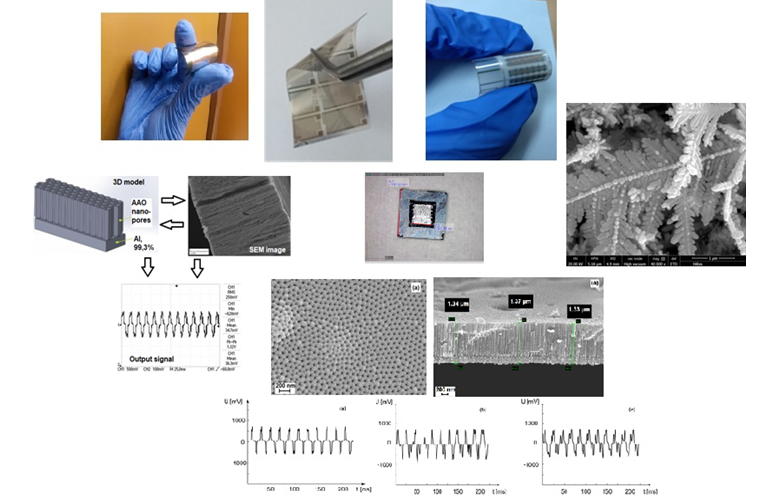

Graphical Abstract

Abstract

Portable and smart electronic devices are powered by batteries whose life is limited. On the other hand, the concept of renewable energy and methods of its obtaining by environmental friendly technologies is gaining. The conversion of energy from various sources at the surrounding environment (energy harvesting) solves the problem of battery-less power supply and satisfies the modern concepts of "clean" energy. One of the mechanisms for electrical energy generation is piezoelectric effect, which relies on mechanical activation (vibrations, pressure, force). A major obstacle for implementation of the thin film piezoelectric generators (PEG) is their low efficiency of about 10-15%. In addition, compared to the stationary PEGs, the flexible ones should fulfil specific requirements such as great durability, ability to follow curves, being light weight and tiny and being able to convert efficiently deformation into electricity at small activating vibrations or forces. Most of the suitable piezoelectric materials are ferroelectric, which significantly broaden their field of application, including ferroelectric memories (FeRAM) and multisensing devices, combining piezoelectric with pyroelectric response. Particularly, the sensors can be used in innovative hardware solutions for mechatronic systems in the transport sector (accelerometers and pressure sensors, activated air bags in the car), acoustic measurements for estimation of noise isolation, vibrational diagnostics for equipment condition monitoring, complex sensor systems for measurement of the ambient environment temperature and atmospheric pressure, infrared sensors for motion detecting, etc. Important application, driving the development of this kind of material is the possibility to integrate sensor and self-sustainable power supply in one device – biomedical implant harvesting energy from natural motions of internal organs and measuring the regularity of their motion as an indication for the health condition. So far, the lead zirconium titanate (PZT) has been considered as the most promising piezoelectric material in terms of conversion efficiency, however, the nowadays concept for lead-free and environmental friendly technology tends to exclude this material from the market competition. New oxide compounds and polymers with piezoelectric properties are now intensively studied to offer the necessary characteristics as required for the modern electronic devices. Their integration in the wearable electronics and the specifics related to their deposition on flexible substrates is novel and still under investigation. It is necessary to extensively explore the PEG stability after multiple bending. It is also necessary application of micro- and nanoelectronic technologies for deposition and patterning of the involved coatings to obtain efficient PEG components with miniature size. Insufficient theoretical and experimental data are available, demonstrating the influence of the type of flexible substrate, electrode materials, type of polymer-based, composite or hybrid piezoelectric materials, deposition process and patterning of the coatings (especially the polymer-based) on the efficient and stable work of PEG at deformation. The nanostructuring of the films is advanced strategy to enhance the sensing properties of the devices. Complex oxides and polymers with controllable morphology at nanoscale, in particular nanorods, nanobranches and nanopores with tuneable dimensions are fabricated in order to increase the specific area and thus to enhance the performance by revealing large surface to bulk ratio. Gained knowledge on the growth and nanostructuring mechanisms and understanding the relation between fabrication processes, crystal structure, composition, thickness, built-in potentials and functional properties of the piezoelectric thin films is of significant importance to design multifunctional devices that fit the needs of the modern low-power and portable electronics. This lecture is an overview of the research done by Assoc. Prof. PhD Mariya Aleksandrova and her group at the Technical University of Sofia, Department of Microelectronics, during the last few years in the field of lead-free piezoelectric materials with energy harvesting and sensing applications.

Keywords

Piezoelectric films; lead-free materials; energy harvesting, multisensory device, microfabrication technology.

Acknowledgement

The author acknowledges Bulgarian National Science Fund, grant number KP06-H27/1.

References

- T. Tsanev, M. Aleksandrova, B. Tzaneva, V. Videkov, Advanced Materials Letters, 2020, 11, 20101566.

- M. Aleksandrova, Advanced Materials Letters, 2020, 11, 20101561.

- M. Aleksandrova, R. Aepuru, G. Dobrikov, IOP Conf. Ser.: Mater. Sci. Eng., 2020, 876, 012006.

- M. Aleksandrova, G. Kolev, Y. Vucheva, H. Pathan, K. Denishev, Applied Sciences, 2017, 7, 890.

- M. Aleksandrova, T. Tsanev, A. Gupta, A.K. Singh, G. Dobrikov, V. Videkov, Materials, 2020, 13, 1777.

Biography

Mariya Aleksandrova received her MSc degree in electronics and the Ph.D. degree in the technology of electronic manufacturing from the TU-Sofia, in 2007 and 2010, respectively. Since 2015, she is an Associate Professor with the Department of Microlectronics, TU-Sofia. She is an author or co-author of 6 books and more than 80 papers in international journals and conference proceedings. Her current research interests include microelectronic technologies, piezoelectric energy harvesting, flexible electronics.

Video Proceedings of Advanced Materials

Upcoming Congress