Video Article Open Access

Overview of Applications of Nanotechnology to Multifunctional Nanocomposites and Renewable Energy Devices at the Hawaii Nanotechnology Laboratories

Mehrdad N. Ghasemi Nejhad

Hawaii Nanotechnology Laboratories, Department of Mechanical Engineering University of Hawaii at Manoa, 2540 Dole Street, Holmes Hall 302, Honolulu, Hawaii, 96822, USA

Vid. Proc. Adv. Mater., Volume 2, Article ID 2021-02115 (2021)

DOI: 10.5185/vpoam.2021.02115

Publication Date (Web): 21 Mar 2021

Copyright © IAAM

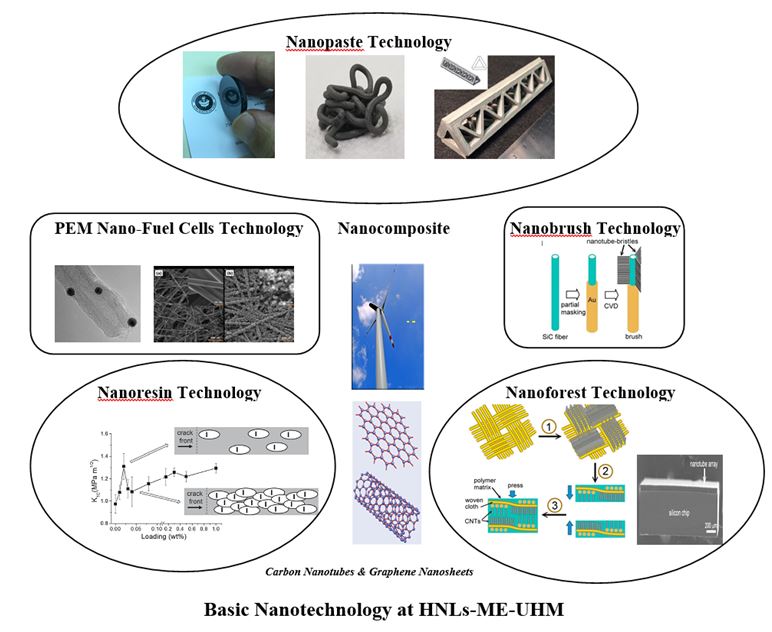

Graphical Abstract

Abstract

This work explains major innovations in terms of science and technology in the multi-disciplinary areas of advanced materials with applications developed at the Hawaii Nanotechnology Laboratories of the Department of Mechanical Engineering of the University of Hawaii at Manoa. These technologies are primarily developed employing functionalized carbon nanotubes (CNTs), Graphene nanosheets (GNSs) and various Nanoparticles (NPs). (1): Nanoresin Technology: Opening up and introducing a new field in the area of nanocomposites by introduction a very low loading of Nanomaterials (GNSs) in the resin systems that enhances the resulting nanocomposites physical and mechanical properties in various fields. In addition, we provided a fracture mechanism that explains the substantial properties improvement of such Nanoresin/Nanocomposites due to a very low loading of Nanomaterials. Sonication systems are employed for the uniform dispersion of Nanomaterials [1]. This technology is also applicable to Wind Turbines. (2): Nanoforest Technology: Opening up and introducing a new field in the area of nanocomposites by the growth of CNT-based nanoforest on fibers or interleaving it within composite layers to produce “hierarchical multifunctional nanocomposites” that enhances the resulting nanocomposites physical and mechanical properties in various fields. Chemical Vapor Deposition (CVD) furnace is used for the growth of Nanoforest [2]. This technology is also applicable to Wind Turbines. (3): Nanobush Technology: Opening up and introducing a new field in the area of small brush by the growth of CNTs on fibers to develop “multifunctional nanobrush” that has applicability in a variety of fields such as NEMS, electronic cleaning, tiny blood vessels cleaning, and environmental cleaning [3]. (4): Renewable Energy Nano-Components Technology: Nanoresin and Nanoforest technologies are employed to develop Nano-Catalyst-Layers and Nano-Gas-Diffusion Layers to enhance the performance, efficiency, and durability while reducing weight, size, and costs of PEM Nano-Fuel-Cells that enhances the resulting electrical and physical properties of the fuel cells. Sonication is used for the uniform dispersion of Platinum nanoparticles and Chemical Vapor Deposition (CVD) furnace is used for the growth of Nanoforest [4]. (5): Nanopaste Technology: Opening up and introducing a new field in the area of advanced ceramic nanocomposites by mixing of various nanomaterials (CNTs, GNSs, NPs) with preceramic polymers, to produce Nanopates that are both moldable and 3D Printable to develop Optical as well as Structural systems. Sonication systems are used for the uniform dispersion of the materials and high-temperature furnaces are used for the curing and pyrolysis of the molded and/or 3D printable ceramic nanocomposites parts [5].

Keywords

Nanoresin, nanoforest, nanobrush, nano-fuel-cells, nanopaste.

Acknowledgement

The author thanks his funding agencies: NASA, Army, Air Force, Navy, Goodman Technologies, and Advanced Silicon Carbide Materials, as well as his MS and PhD students and Post-Doctoral Fellows throughout these projects.

References

- Y. T. Park, Y. Qian, C. Chan, T. Suh, M. Ghasemi Nejhad, C. Macosko, A. Stein, “Epoxy Toughening with Low Graphene Loading,” Advanced Functional Materials, 2015, 25, 575-585.

- V.P. Veedu, A. Cao, X. Li, K. Ma, C. Soldano, P.M. Ajayan, M.N. Ghasemi-Nejhad, "Multifunctional composites using reinforced laminae with carbon-nanotube forests," Nature Materials, 2006, 5, 457-462.

- A. Cao, V. P. Veedu, X. Li, Z. Yao, M. N. Ghasemi-Nejhad, P. M. Ajayan, "Multifunctional brushes made from carbon nanotubes," Nature Materials, 2005, 4, 540-545.

- P. A. Stuckey, J. F. Lin, A. M. Kannan, M. N. Ghasemi Nejhad, “Gas Diffusion Layers for Proton Exchange Membrane Fuel Cells Using in situ Modified Carbon Papers with Multi-walled Carbon Nanotubes Nanoforest,” Fuel Cells, 2010, 10, 69-374.

- W. A. Goodman, M. N. Ghasemi Nejhad, B. M. Minei, J. A. Stuecker, T. M. Anderson, “Ultra-lightweight ultra-stable RoboSiC™ additively manufactured lasercom telescope,” SPIE Conference on Optomechanics and Optical Manufacturing; Material Technologies and Applications to Optics, Structures, Components, and Sub-Systems IV (Conference OP304); Chairs: Matthias Krödel; William A. Goodman; Aug. 11-15, 2019, San Diego, CA, Paper 11101-16 (Invited Paper), 1-8.

Biography

Mehrdad N. Ghasemi Nejhad is Professor and Director of the Hawaii Nanotechnology Laboratories at the Department of Mechanical Engineering (ME) of the University of Hawaii at Manoa (UHM). He received his Ph.D. degree in ME and Center for Composite Materials (CCM) from the University of Delaware (UD-1992). He is an invited speaker, contributor, and reviewer of journal articles in nanotechnology, composites/nanocomposites, smart structures, and renewable energy, and is the Associate Editor for Journal of Thermoplastic Composite Materials.

Dr. Ghasemi-Nejhad is an ASME Fellow, Boeing Welliver Faculty Fellow, and has been a member of ASME, SPIE, ASC, SAMPE, and SAE. He is a member of Adaptive Structures and Material Systems (ASMS) of ASME/Aerospace, Co-Chair/Chair of ASMS Symposium in ASME/IMECE (2006-2007); Chair of the First ASME International Conference on Multifunctional Nanocomposites (2006), and Co-Chair/Chair of Active and Passive Structures and Integrated Systems for SPIE Conferences (2008-2009/2010-2011). He has also been student faculty advisor for SAMPE, ASME-HPV, and SAE Mini Baja/Supermileage/Formula/AeroDesign senior projects. Prof. Ghasemi-Nejhad was the ME Chair (8 years) and the ABET Chair (about 20 years). He has over 170 publications in nanotechnology, composites/nanocomposites, smart structures, and thin films, including publications in Nature Materials and Science, and has five national/international patents with another four pending, in nanotechnology and composites/nanocomposites.

Dr. Ghasemi-Nejhad is a recipient of Block Fellowship (UD, 1990), DuPont Fellowship (1991), Scholars Award (CCM, UD, 1991), Presidential Citation for Meritorious Teaching (UHM, 1998), ASME Region IX Outstanding Faculty Advisor Award (2001), Best Paper Award in Mechanics of Materials (ASME/Aerospace-ASMS, 2007). With his students, he won the HPV National Championship in 1995 and 1997. He is one of the inventors of the Nanobrush, “World’s Smallest Brush”, certificated by the 2007 Guinness Book of World Record. He has won the UHM Business Plan Competitions (2008 & 2012), and subsequently founded two start-up companies.

Video Proceedings of Advanced Materials

Upcoming Congress