Video Article Open Access

Effect of Prewetted Ceramsite Content on Autogenous Shrinkage of Alkali-Activated Slag Concrete

Tao Ji*, Qi-lin Zhang, Ke-jia Cheng

College of Civil Engineering, Fuzhou University, Fuzhou, Fujian 350116, China

Vid. Proc. Adv. Mater., Volume 2, Article ID 2021-0168 (2021)

DOI: 10.5185/vpoam.2021.0168

Publication Date (Web): 25 Jan 2021

Copyright © IAAM

Graphical Abstract

Abstract

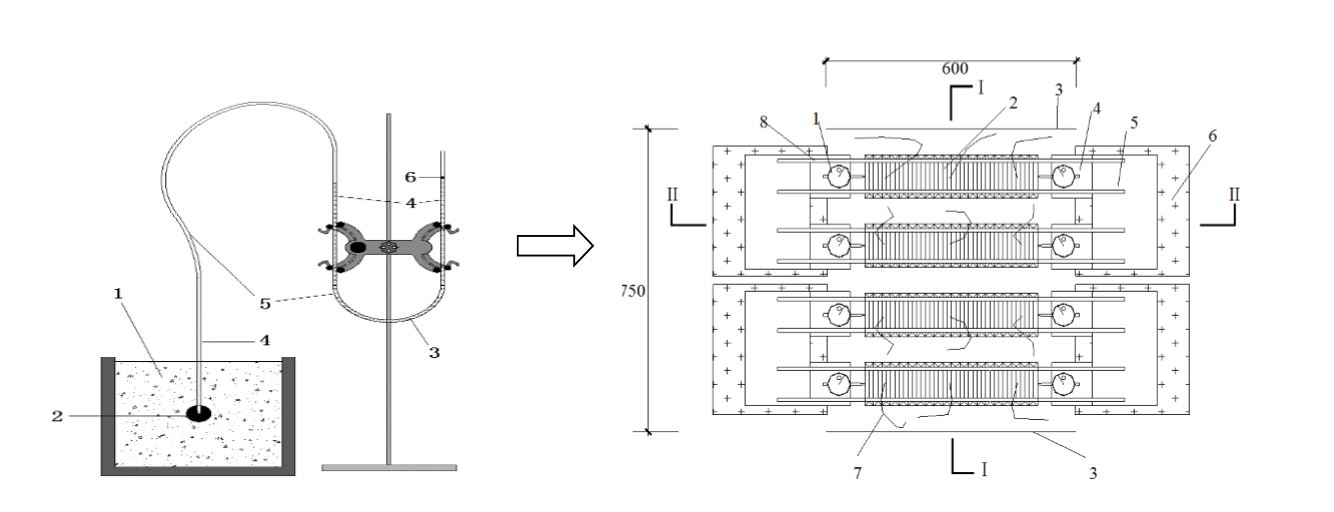

Alkali-activated slag (AAS) has the advantages of simple production technology, low cost, energy saving, environment friendliness and especially the utilization of industrial solid waste. Therefore, AAS is a sustainable material. However, the shrinkage of alkali-activated slag concrete (AASC) is much larger than that of ordinary Partland cement concrete (OPCC). Lightweight aggregate (LWA) can release water for internal curing in lightweight aggregate concrete (LWAC) due to the water absorption and desorption capability of LWA. The early age autogeneous shrinkage of LWAC decreases with the increase of prewetting degree of ceramsite. In contract to ordinary Partland cement (OPC) concrete, the water absorption and desorption process of prewetted ceramsite in AASC was investigated by using an U-tube mico-pressure measurement device. The investigation parameters include the type of cement (OPC and AAS) and 24 h-prewetted ceramsite contents. Combined with the test results of pore structure, SEM and mechanical behavior (compressive strength, splitting tensile strength and elastic modulus), the effect of prewetted ceramsite contents on the autogenous shrinkage of AASC in 14 days was studied by a in-house corrugated pipe device. The results show that, compared with OPCC, the amount of water absorption and desorption of AASC is less, and the ratios of less harmful and harmless pores to total pore volume of AASC is significantly larger. Meanwhile in AASC there is no Ca(OH)2 that can restraint the autogenous shrinkage. Consequently, the autogenous shrinkage of AASC is larger than that of OPCC. Due to the “internal curing” effect, the higher the prewetted ceramsite content is, the smaller the water absorption and desorption amount and time are, the smaller total pore volume, average pore size and the proportion of the cumulative pore volume whose diameter is greater than 50 nm are. On the other hand, the prewetted ceramsite provides water for cement hydration, and improves the internal relative humidity in AASC. Therefore, with the increase of the prewetted ceramsite content, the autogenous shrinkage of AASC decreases effectively. Because the proportions of less harmful pores and harmless pores of AASC are much greater than that of OPCC, the beneficial effect of the prewetted ceramsite content on the internal relative humidity of AASC is greater than that of OPCC. Therefore, the effect of the prewetted ceramsite content on reducing the autogenous shrinkage of AASC is greater than that of OPCC.

Keywords

Combined activator, ceramsite, autogenous shrinkage, alkali-activated slag concrete.

Acknowledgement

The financial support from NSFC (National Nature Science Foundation of China) (Grant Number 51878179) is gratefully acknowledged.

References

- T Ji, B B Zhang, Y Z Zhuang; ACI Materials Journal, 2015, 112, 355-363.

- J. L. Provis, A. Palomo, C. Shi; Cement and Concrete Research, 2015, 78, 110-125.

- Y. N. Chen, T Ji, Z. X. Yang, W. Zhan, Y. Zhang; Construction and Building Materials, 2020, 240, 117969.

Biography

Tao Ji is professor in the College of Civil Engineering, Fuzhou University, China. He obtained his B.Sc. from Harbin University of Architecture in 1994, his master from Fuzhou University in 1997, and Ph.D. from Zhejiang University in 2000. Dr. Ji has been engaged in research related to solid waste utilization, environmental protection cement-based materials and engineering application for a long time. He hosted 2 general projects of National Natural Science Foundation of China, one major project of science and technology cooperation between industry and University of Fujian Province. He has won twice third prizes for scientific and technological progress in Fujian Province, 27 authorized invention patents, one software copyright and two published works. He published more than 130 papers in academic journals, including 40 academic papers indexed by SCI. The highest number of citations for a single paper is more than 600. He edited two standards of engineering construction standardization association and participated in three national and provincial standards. Dr. Ji is member of the U.S. Transportation Research Board, member of construction solid waste special committee of China Silicate Society, member of chemical activated cementitious materials professional committee of China Construction Society, director of education and human resources committee of the China Concrete and Cement Products Association, and expert of Fujian Green Building Review.

Video Proceedings of Advanced Materials

Upcoming Congress