Video Article Open Access

Phase Change Materials Reinforced with Aluminium Foam for Latent Heat Storage

Jaroslav Jerz1,*, Arun Gopinathan1,2, Jaroslav Kováčik1

1Institute of Materials & Machine Mechanics, Slovak Academy of Sciences, Bratislava, Slovakia

2Faculty of Materials Science and Technology, Slovak University of Technology, Trnava, Slovakia

Vid. Proc. Adv. Mater., Volume 2, Article ID 2021-0146 (2021)

DOI: 10.5185/vpoam.2021.0146

Publication Date (Web): 16 Jan 2021

Copyright © IAAM

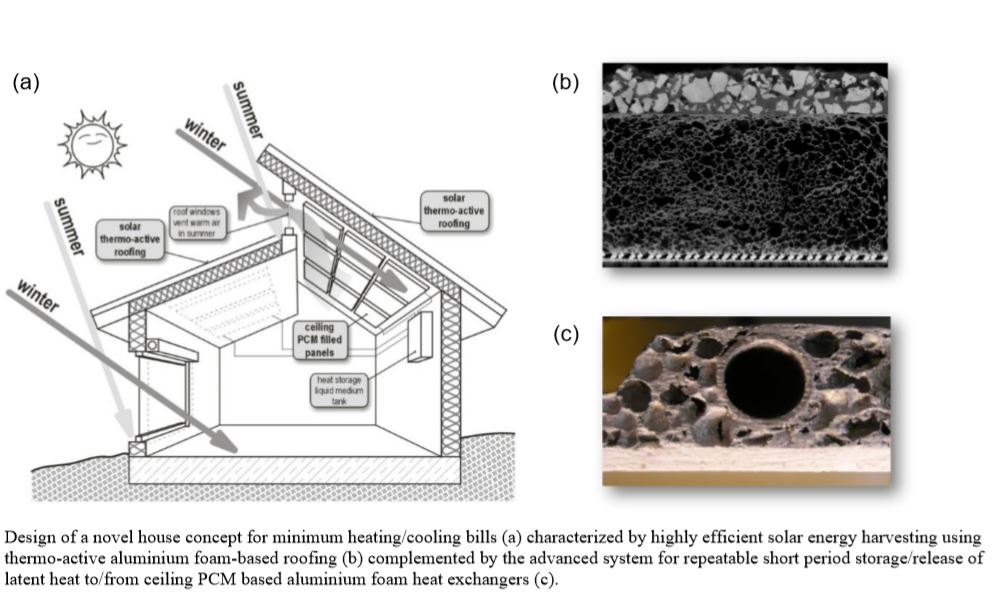

Graphical Abstract

Abstract

The structure of aluminium foam is highly porous consisting of aluminium (or its alloy) filling up the space among gas pores. Although pores formed during foaming of aluminium melt are closed, there are always microscopic cracks in the walls of solid foam, so that the porosity is predominantly open. This preference of aluminium foam allows to fill pores with a Phase Change Materials (PCMs) capable repeatedly to store and release a huge amount of latent heat of phase transformation from solid to liquid state and vice versa. The excellent thermal conductivity of the aluminium, forming the pore walls, predetermines aluminium foam castings for the production of highly efficient heat exchangers in various industrial sectors, especially in the building industry. The most promising technique for the production of near-net-shaped structural components containing a dense aluminium surface skin and porous inner foamed aluminium structure is powder metallurgical route. Lightweight self-supporting interior ceiling panels impregnated by PCM presented in this contribution, utilize their high mechanical stiffness and their ability to store large amounts of latent heat at a constant temperature. The application of foamed aluminium appears to be very promising also for heat exchangers covering the entire pitched roof of the building which provides not only the better recovery of the heat from the building surroundings but also the dissipation of unwanted excess heat from the interior when needed.

Keywords

Aluminium foam; heat exchangers; phase change materials; heat storage; energy efficiency.

Acknowledgement

The financial support by the Slovak Research and Development Agency under the contract APVV-17-0580 (Project: Research of roofing with integrated function of heat exchanger, acronym: RoofFoam) is gratefully acknowledged.

References

- J. Jerz et al., Advanced Materials Letters, 2019, 10, 351. ISSN 0976-3961.

- A. Gopinathan et al., MTSM Split, 2019, 53. ISSN 1847-7917.

- J. Jerz et al., Int. J. of Innovative Res. in Sci., Eng. and Technology, 2015, 4(8), 6722. ISSN 2319-8753.

Biography

Jaroslav Jerz has completed his PhD from Vienna University of Technology (Austria) with dissertation dedicated to the development of aluminum foam by powder metallurgy. He is a scientist at the Institute of Materials & Machine Mechanics of Slovak Academy of Sciences in Bratislava (Slovakia). His work is devoted mainly to the field of materials engineering and related investigation of efficient management of production and consumption of energy from renewable sources. He also performs development, testing and industrial commercialization of novel ceiling aluminum foam heating/cooling panels as well as thermally active aluminum foam-based roofing systems. His scientific work is devoted to advanced metallic materials, development of technologies for their industrial production and transfer of knowledge gained by material research into industrial practice.

Video Proceedings of Advanced Materials

Upcoming Congress